- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Cost Analysis of Aluminum Grating Options for Your Next Project

Understanding the Price of Aluminum Grating Factors and Considerations

Aluminum grating is an essential component in various industrial and commercial applications. Its lightweight, corrosion-resistant, and durable characteristics make it an ideal choice for flooring, walkways, and platforms. However, one question arises frequently among buyers “What influences the price of aluminum grating?” This article aims to explore the various factors that contribute to the pricing of aluminum grating and provide insights into making informed purchasing decisions.

Material Quality and Type

The primary factor affecting the price of aluminum grating is the quality of the aluminum used in its manufacturing. Aluminum grating is typically made from high-grade aluminum alloys that enhance its strength and durability. Higher-grade materials often come at a premium price. Furthermore, there are different types of aluminum grating, such as welded or swage-locked, each with its own production methods and costs. Understanding the specific requirements of your project can help you choose the right type that balances cost and functionality.

Manufacturing Process

The complexity of the manufacturing process also plays a significant role in determining the price. Aluminum grating can be produced through various methods, including casting and extrusion. Each method has its cost implications based on the equipment required, labor, and time involved. For instance, welded grating, which typically offers increased strength, may be more expensive due to the rigorous welding process compared to lighter-weight alternatives.

Size and Configuration

The dimensions and configuration of the aluminum grating often influence the final price. Standard sizes may come at a lower cost due to economies of scale in production, while custom-sized grating may incur additional costs. Moreover, specific designs, such as serrated surfaces for slip resistance or specific load-bearing requirements, can also affect pricing. It is essential to provide detailed specifications to manufacturers to get accurate quotes based on your needs.

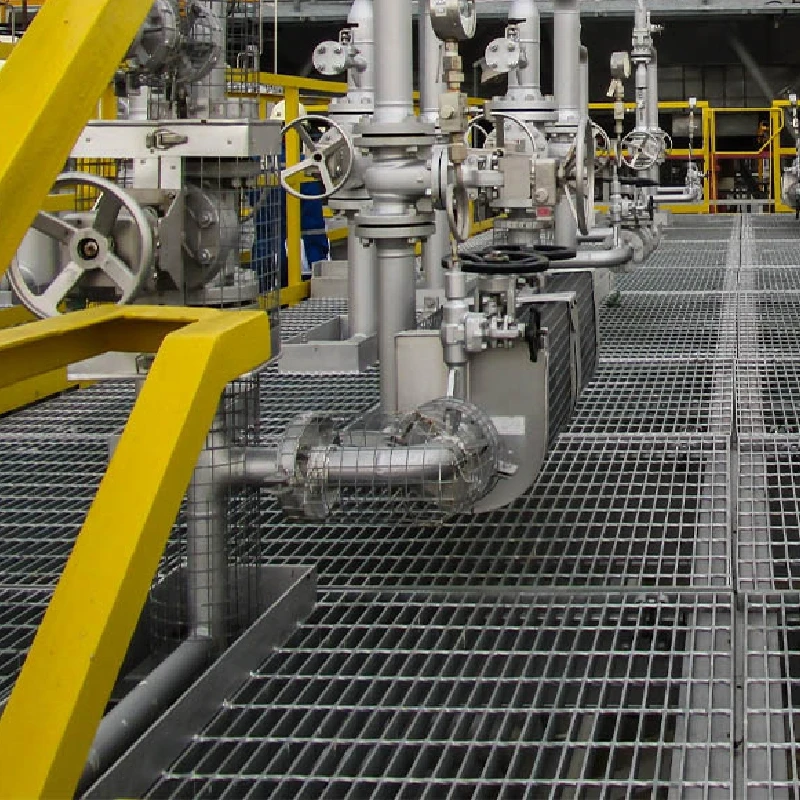

aluminum grating price

Surface Treatments and Finishes

Many buyers opt for additional surface treatments to enhance the performance of aluminum grating. Options such as anodizing or powder coating can provide extra protection against corrosion and improve aesthetic appeal. However, these treatments come at an added cost. Therefore, users must weigh the benefits of enhanced durability and appearance against their budget constraints.

Quantity and Bulk Orders

Pricing strategies can also vary based on the quantity of aluminum grating ordered. Manufacturers often offer discounts for bulk purchases, making it more cost-effective to buy larger quantities. Additionally, negotiating with suppliers for volume pricing can lead to significant savings. If you anticipate needing aluminum grating over time, planning ahead and purchasing in bulk could be a beneficial strategy.

Market Dynamics and Location

Market dynamics, such as demand and supply fluctuations, can influence prices. Economic factors, including the cost of raw materials and tariffs on imports, can also affect the final pricing of aluminum grating. Furthermore, the location of the supplier and transportation costs can impact the overall price. Local suppliers might offer better prices due to reduced shipping costs compared to those who ship from distant locations.

Conclusion

In conclusion, the price of aluminum grating is influenced by a myriad of factors, including material quality, manufacturing processes, size, surface treatments, order quantities, and market dynamics. For potential buyers, understanding these factors is crucial to making informed decisions. It is advisable to compare quotes from multiple suppliers, assess your specific project needs, and consider the long-term benefits versus initial costs. By taking these considerations into account, you can ensure that you select the right aluminum grating solution that fits both your budget and performance requirements.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024