- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

concrete weight coating pipe

Concrete Weight Coating for Pipes An Overview

Concrete weight coating is a vital process in the pipeline industry, particularly in applications involving underwater and buried pipelines. This technique involves applying a layer of concrete to steel pipes to provide additional weight, stability, and protection against environmental factors. The coating serves multiple essential functions, making it indispensable for transporting oil, gas, and water across various terrains.

Concrete Weight Coating for Pipes An Overview

Moreover, concrete weight coating offers protection against external forces that pipelines might encounter in harsh environments. For instance, underwater pipelines must withstand currents, tidal changes, and the impact of marine life. The concrete layer acts as a shield, absorbing shocks and preventing structural damage. In terrestrial applications, it provides resistance against soil movement and erosion, ensuring the integrity of the pipeline over time.

concrete weight coating pipe

In addition to stability and protection, concrete weight coating can enhance the longevity of pipelines. The concrete layer prevents corrosion, which is a significant concern for metallic pipelines. By providing a physical barrier, it reduces the exposure of steel to water and aggressive soil conditions. The durability of the concrete, combined with proper application techniques, can significantly extend the life span of the pipelines, translating into cost savings for companies.

The application process of concrete weight coating typically involves several steps. First, the steel pipe is pre-treated to ensure proper adhesion of the concrete. Next, a layer of specialized concrete mixture is applied, which is often augmented with additives to improve its strength and durability. Once the coating is applied, it must cure adequately, allowing the concrete to harden and gain its full protective qualities. The entire process necessitates skilled labor and careful monitoring to ensure a high-quality finish.

An essential aspect of concrete weight coating is its adaptability. Different projects require varying thicknesses and weights, depending on environmental conditions and pipeline specifications. Engineers can tailor the coating to meet specific requirements, making it a versatile solution in numerous scenarios.

In conclusion, concrete weight coating is a crucial procedure in ensuring the safety, stability, and longevity of pipelines used in challenging environments. Its ability to provide necessary weight, protection from external forces, and resistance to corrosion makes it an invaluable practice in the pipeline industry. As technology advances, ongoing improvements in materials and application techniques will likely enhance the efficiency and effectiveness of concrete weight coating, thereby supporting the industry's evolving needs.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

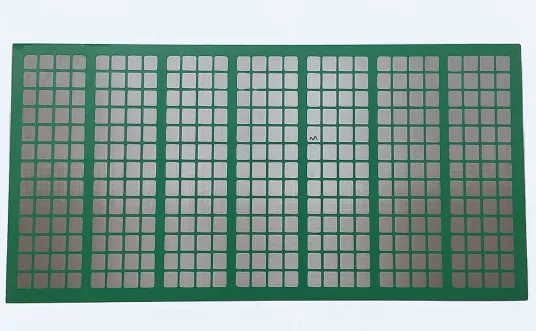

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024