- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

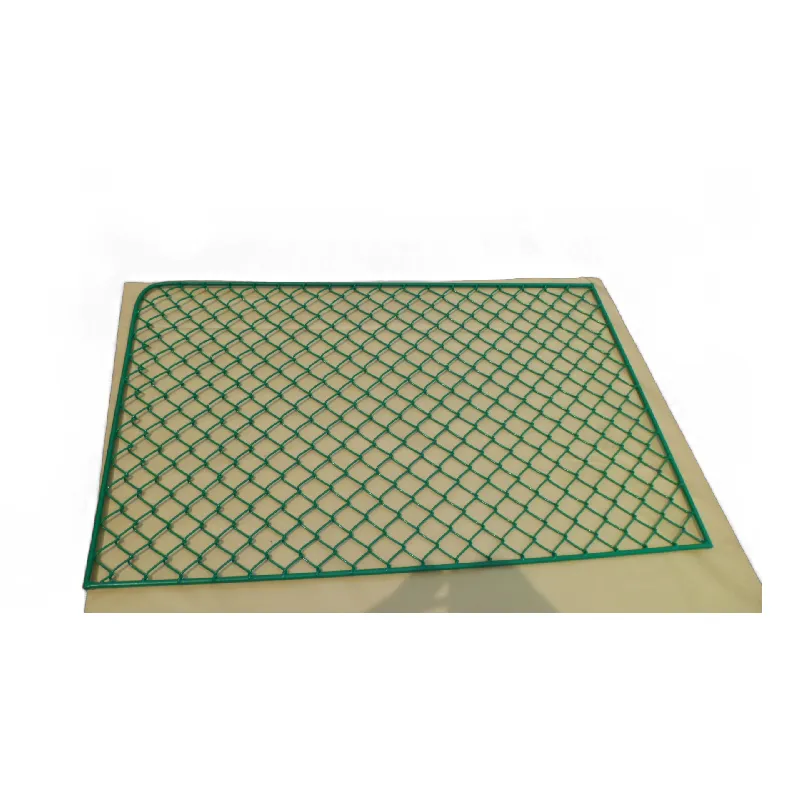

High-Quality Concrete Weight Coating Mesh for Pipeline Protection

Concrete Weight Coating Mesh An Essential Component in Pipeline Protection

Concrete weight coating mesh plays a critical role in the pipeline industry, particularly in the construction and installation of underwater pipelines. As oil and gas are transported across vast distances, ensuring the safety and stability of these pipelines becomes paramount. This is where concrete weight coating mesh comes into play, providing robust protection against various environmental factors while ensuring the pipelines remain submerged and stable.

Understanding Concrete Weight Coating

Concrete weight coating is a method used to provide mass to pipelines, allowing them to resist buoyancy in water. This is particularly crucial for underwater or submerged pipelines, as they must counteract the natural tendency to float. Typically, concrete is applied to the outer surface of the pipe, creating a heavy layer that acts as a stabilizing force. The concrete weight coating mesh is an integral part of this process, serving to reinforce the concrete and enhance its structural integrity.

The Role of Mesh in Weight Coating

The mesh used in concrete weight coating serves multiple purposes. Firstly, it acts as a bonding agent, improving the adherence of the concrete to the pipe surface. This ensures that the weight coating remains intact and effective over time, even when subjected to harsh marine environments. Secondly, the mesh enhances the tensile strength of the concrete, allowing it to withstand the stresses and strains that may occur during installation and operation.

concrete weight coating mesh

Moreover, the mesh helps distribute the weight of the concrete evenly across the pipeline. This is essential to prevent localized stress which could lead to pipeline failure. As such, the design and material of the mesh are critically important — typically, high-strength steel wire is used to ensure durability and reliability.

Applications and Benefits

Concrete weight coating mesh is primarily used in the oil and gas sector, where pipelines are laid on the seabed and must withstand varying environmental conditions. However, its use is not limited to this industry. It can also be found in water treatment plants, sewage systems, and other applications where underground or underwater pipeline stability is necessary.

The benefits of using concrete weight coating mesh are manifold. Firstly, it provides enhanced protection against external forces such as tidal currents, impacts from marine life, and debris movement, thereby reducing the risk of damage to the pipeline. Secondly, it offers thermal insulation, which can be vital in preventing issues related to temperature variations underwater. Lastly, the use of concrete weight coating mesh can extend the lifespan of pipelines, leading to cost savings in maintenance and repairs.

Conclusion

As the demand for energy continues to grow, ensuring the integrity of pipelines is more crucial than ever. Concrete weight coating mesh is a vital component that helps achieve this goal, providing the necessary weight, protection, and structural stability for submerged pipelines. By understanding its role and benefits, stakeholders in the pipeline industry can make informed decisions regarding their infrastructure investments. As technology advances and materials improve, the effectiveness and capabilities of concrete weight coating mesh will likely continue to evolve, playing an essential role in the future of pipeline protection and installation.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024