- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 18, 2025 01:13

Back to list

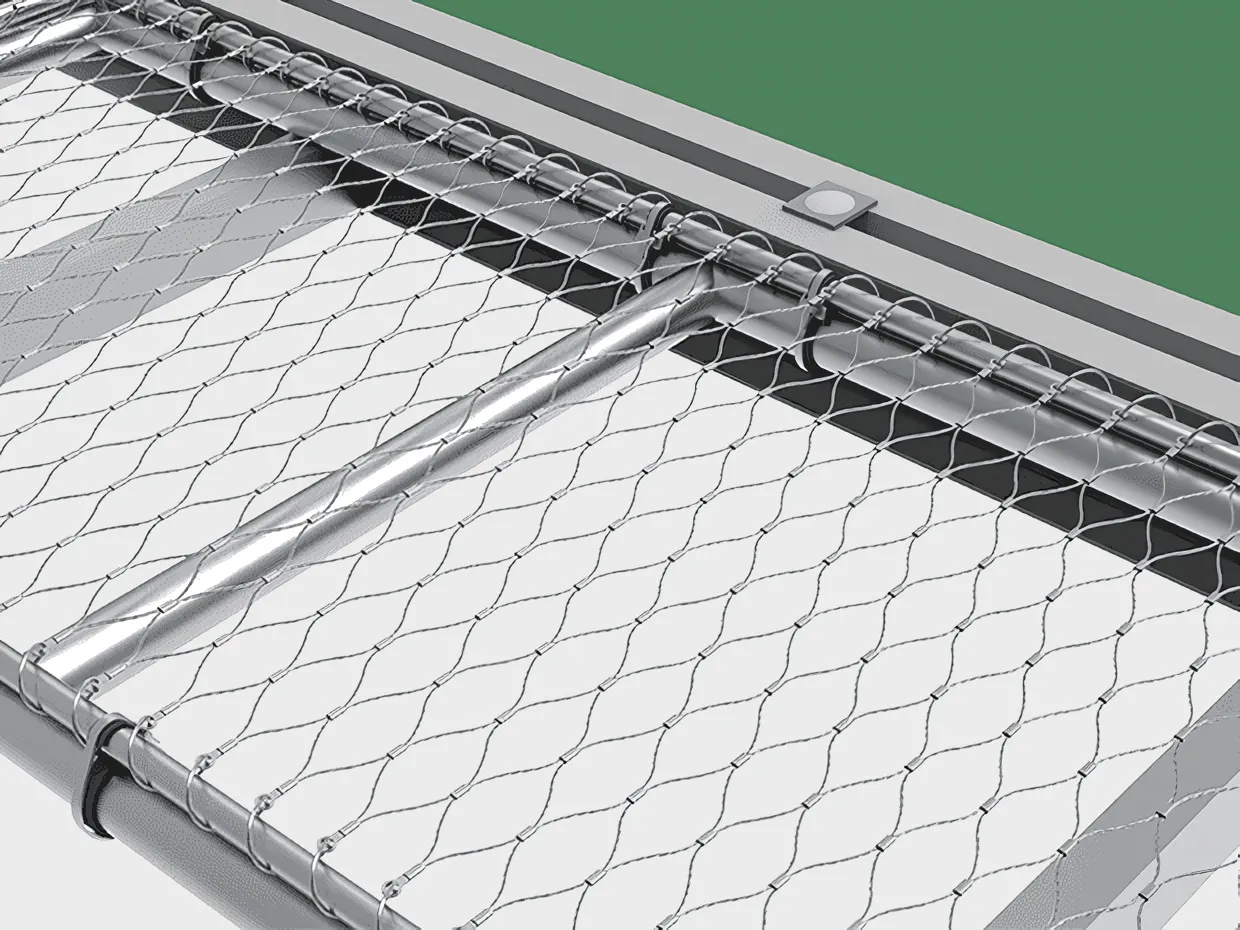

Composite Frame Shaker Screen

Expert Guide to Channel Drain Grate Replacement Ensuring Efficient Drainage Systems

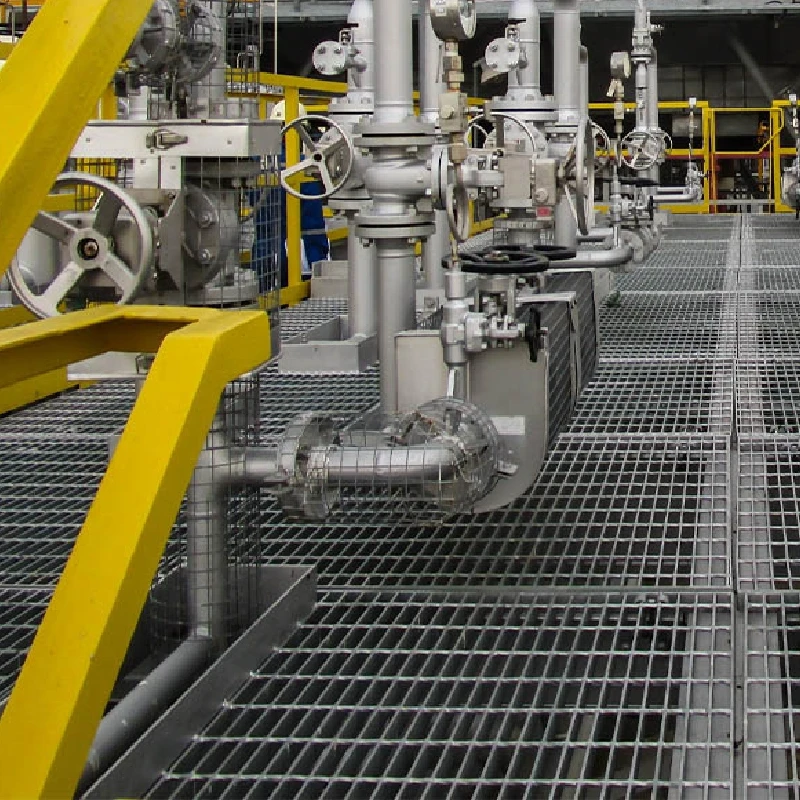

1. Safety First Prioritize safety during the replacement process by donning appropriate personal protective equipment. Moreover, ensure the working area is clearly marked to minimize the risk of accidents. 2. Removal of Old Grate Use appropriate tools to lift and remove the damaged grate carefully. This step may require a crowbar or a specific removal tool depending on the grate design. 3. Inspection and Cleaning Before installing the new grate, inspect the channel drain for any underlying damage or blockages. Clean the channel bay thoroughly to prevent future drainage issues. 4. Correct Positioning Place the new grate, ensuring it sits flush with the channel and surrounding surfaces to avoid trip hazards and potential misalignments during usage. 5. Secure Placement Utilize any provided locking mechanisms to secure the grate firmly in place. This may involve screw fittings, clips, or snap-on systems depending on the grate model and design. Maintenance Tips for Longevity To ensure longevity, schedule regular maintenance and inspections post-installation. This includes clearing blockages, checking for early signs of wear, and cleaning the grates to prevent buildup. Adequate maintenance not only extends the lifespan of the drain system but also ensures continued functional effectiveness. Expertise and Trust in Product Selection When selecting replacement grates, sourcing from reputable vendors assures quality and reliability. Trusted brands can provide product certifications, warranty assurances, and expert advice tailored to specific project needs. Investing in high-quality grates, although initially more costly, translates into longer product life and reduced risk of failure, reflecting responsible resource allocation. In conclusion, channel drain grate replacement, while seemingly straightforward, demands careful material selection, proper installation, and continuous maintenance to ensure sustained performance. Committing to informed choices based on expert advice and trustworthy supplier relationships fosters not only the effectiveness of your drainage system but also its resilience in the face of environmental challenges.

1. Safety First Prioritize safety during the replacement process by donning appropriate personal protective equipment. Moreover, ensure the working area is clearly marked to minimize the risk of accidents. 2. Removal of Old Grate Use appropriate tools to lift and remove the damaged grate carefully. This step may require a crowbar or a specific removal tool depending on the grate design. 3. Inspection and Cleaning Before installing the new grate, inspect the channel drain for any underlying damage or blockages. Clean the channel bay thoroughly to prevent future drainage issues. 4. Correct Positioning Place the new grate, ensuring it sits flush with the channel and surrounding surfaces to avoid trip hazards and potential misalignments during usage. 5. Secure Placement Utilize any provided locking mechanisms to secure the grate firmly in place. This may involve screw fittings, clips, or snap-on systems depending on the grate model and design. Maintenance Tips for Longevity To ensure longevity, schedule regular maintenance and inspections post-installation. This includes clearing blockages, checking for early signs of wear, and cleaning the grates to prevent buildup. Adequate maintenance not only extends the lifespan of the drain system but also ensures continued functional effectiveness. Expertise and Trust in Product Selection When selecting replacement grates, sourcing from reputable vendors assures quality and reliability. Trusted brands can provide product certifications, warranty assurances, and expert advice tailored to specific project needs. Investing in high-quality grates, although initially more costly, translates into longer product life and reduced risk of failure, reflecting responsible resource allocation. In conclusion, channel drain grate replacement, while seemingly straightforward, demands careful material selection, proper installation, and continuous maintenance to ensure sustained performance. Committing to informed choices based on expert advice and trustworthy supplier relationships fosters not only the effectiveness of your drainage system but also its resilience in the face of environmental challenges.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024