- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

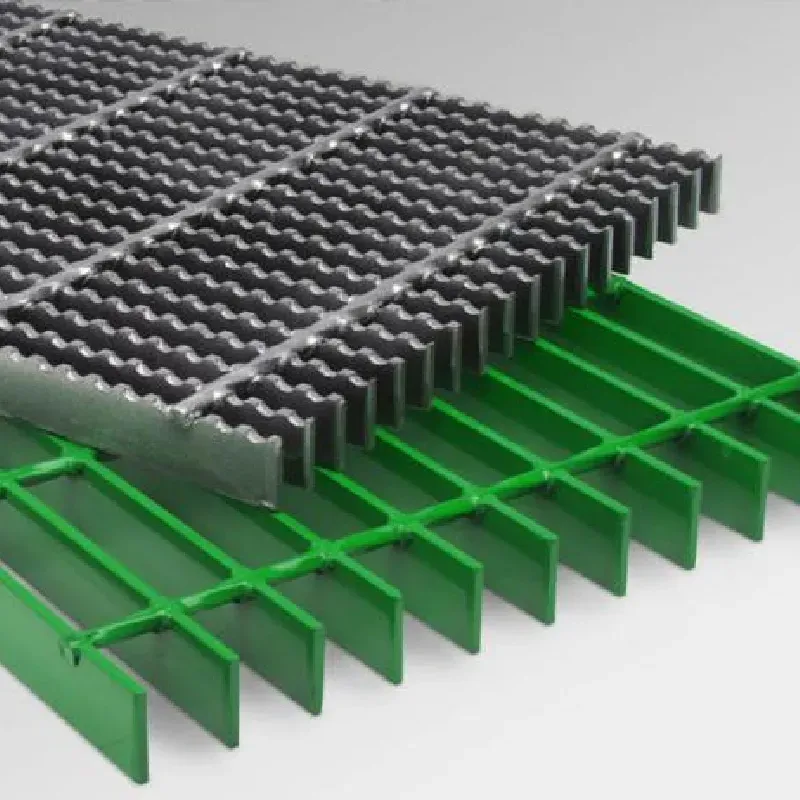

Best Deals on Durable Steel Grating for Your Needs

Buying Steel Grating A Comprehensive Guide

When it comes to construction and industrial applications, steel grating is often an essential component. This versatile product is used in a variety of settings, from walkways and platforms to drainage covers and security fencing. Understanding the factors to consider when buying steel grating is crucial for ensuring you choose the right product for your project.

What is Steel Grating?

Steel grating is a type of material made from a series of parallel bars that are joined together, forming an open-grid structure. This design allows light, air, and fluids to pass through while providing a strong support system. The material is durable and resistant to corrosion, making it suitable for both indoor and outdoor applications.

Factors to Consider When Buying Steel Grating

1. Type of Grating There are several types of steel grating, including welded steel grating, press-locked steel grating, and swage-locked steel grating. Welded steel grating is the most common, where the bars are welded together at intersections. Press-locked grating offers a more aesthetically pleasing look and is easier to handle. Swage-locked grating provides a high load-bearing capacity, ideal for heavy-duty applications. Understanding the specific requirements of your project will help you choose the right type.

2. Load Capacity One of the primary considerations when selecting steel grating is the load capacity it can handle. This factor is determined by the spacing between the bars, the thickness of the material, and the type of application. It is vital to assess the expected load to ensure safety and durability.

buy steel grating

3. Material and Coating The most commonly used material for steel grating is mild steel, but options like stainless steel and aluminum are also available for specific needs, such as corrosion resistance. Furthermore, consider whether a coating is necessary to enhance durability. Galvanized or powder-coated finishes can provide additional protection against rust and wear.

4. Dimensions and Customization Steel grating comes in various standard sizes, but custom dimensions may be required for specific applications. Before making a purchase, measure the area where the grating will be installed to ensure a proper fit. Many manufacturers offer custom fabrication services to meet individual specifications.

5. Cost and Supplier Price can vary significantly based on material, type, and customization. It is advisable to obtain quotes from multiple suppliers to compare prices. Look for reputable manufacturers who offer quality products, good customer service, and warranties. This can save you money in the long run by avoiding premature replacements.

6. Installation Lastly, consider the installation process. Some types of steel grating can be installed easily, while others may require professional assistance. Factor in these costs when planning your budget.

Conclusion

Buying steel grating involves understanding various factors, including types, load capacity, material, dimensions, and costs. By considering these elements, you can make an informed decision that ensures your project's success. Whether you're looking for aesthetics, durability, or strength, there is a steel grating solution tailored to your needs. With the right choice, steel grating can provide a safe, functional, and long-lasting addition to your construction project.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024