- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 12, 2025 01:55

Back to list

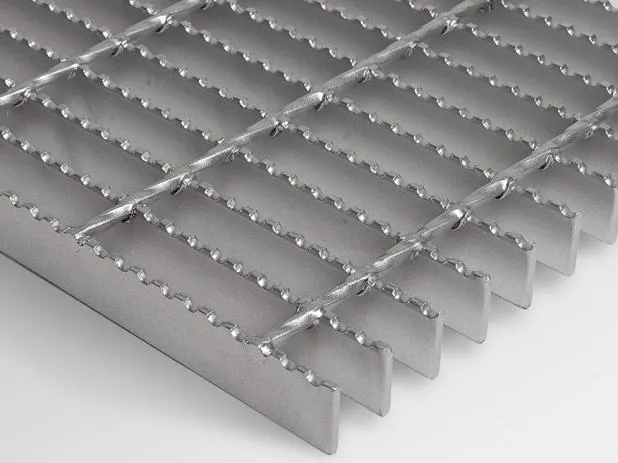

heavy-duty welded bar grating

Bar steel grating stands as a pivotal component in the industrial and architectural sectors, celebrated for its blend of strength, durability, and versatility. Whether it's in manufacturing plants, bridges, or large commercial buildings, the use of bar steel grating is critical due to its ability to withstand extreme conditions while providing safety and support.

From a safety perspective, the trustworthy design of bar steel grating cannot be overstated. Industries prone to slick conditions, such as oil and gas, benefit from its anti-slip properties. The grating's serrated surface provides the necessary grip, reducing accidents and enhancing the safety of personnel. Furthermore, compliance with industry standards and regulations is often guaranteed, adding to the grating’s authoritative stature as a go-to safety solution. The trustworthiness of a supplier is a crucial element in the procurement process. Professionals seeking bar steel grating must ensure their sources meet strict quality control standards. Expert manufacturers often provide customized solutions tailored to specific project needs, ensuring the client receives a product that aligns perfectly with their structural requirements. Engaging with reputed vendors, who uphold certifications and demonstrate a commitment to quality, guarantees that the grating will perform as expected under all specified conditions. When discussing the environmental impact, bar steel grating scores high on sustainability metrics. Constructed primarily of steel, one of the most recyclable materials, it aligns with eco-friendly practices. This recyclability ensures that once the grating reaches the end of its life cycle, it can be reused, thus reducing waste and contributing to a more sustainable construction industry. In conclusion, bar steel grating continues to demonstrate its indispensable role across various sectors due to its multifaceted applications, robust nature, and aesthetic potential. Professionals relying on this material can expect not just functionality and compliance, but also a reliable partnership with respect to product lifecycle management and environmental consideration. This perfect blend of experience, expertise, authoritative compliance, and trustworthiness makes bar steel grating a premier choice for any project requiring lasting durability and reliability.

From a safety perspective, the trustworthy design of bar steel grating cannot be overstated. Industries prone to slick conditions, such as oil and gas, benefit from its anti-slip properties. The grating's serrated surface provides the necessary grip, reducing accidents and enhancing the safety of personnel. Furthermore, compliance with industry standards and regulations is often guaranteed, adding to the grating’s authoritative stature as a go-to safety solution. The trustworthiness of a supplier is a crucial element in the procurement process. Professionals seeking bar steel grating must ensure their sources meet strict quality control standards. Expert manufacturers often provide customized solutions tailored to specific project needs, ensuring the client receives a product that aligns perfectly with their structural requirements. Engaging with reputed vendors, who uphold certifications and demonstrate a commitment to quality, guarantees that the grating will perform as expected under all specified conditions. When discussing the environmental impact, bar steel grating scores high on sustainability metrics. Constructed primarily of steel, one of the most recyclable materials, it aligns with eco-friendly practices. This recyclability ensures that once the grating reaches the end of its life cycle, it can be reused, thus reducing waste and contributing to a more sustainable construction industry. In conclusion, bar steel grating continues to demonstrate its indispensable role across various sectors due to its multifaceted applications, robust nature, and aesthetic potential. Professionals relying on this material can expect not just functionality and compliance, but also a reliable partnership with respect to product lifecycle management and environmental consideration. This perfect blend of experience, expertise, authoritative compliance, and trustworthiness makes bar steel grating a premier choice for any project requiring lasting durability and reliability.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024