- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Calculating Weight of Bar Grating per Square Foot for Various Applications

Understanding Bar Grating Weight Per Square Foot

Bar grating is a crucial component in a variety of industrial and commercial applications, widely used for flooring, walkways, drainage covers, and platforms. Its strength, durability, and versatility make it an ideal choice in environments ranging from manufacturing plants to municipal facilities. However, an essential aspect often overlooked in the planning and installation of bar grating is its weight per square foot. This measurement not only affects shipping costs and installation methods but also has implications for structural support and overall safety. In this article, we will explore the factors influencing the weight of bar grating and why it matters in practical applications.

What is Bar Grating?

Bar grating consists of a series of parallel bars, either made of steel, aluminum, or fiberglass, welded or mechanically fastened together to provide a robust surface. The two primary types of bar grating are welded and press-locked, each offering unique benefits in terms of load capacity and design flexibility. The weight of bar grating varies based on its material, design, and dimensions, such as bar thickness and spacing. Understanding these factors is essential for engineers, architects, and construction managers when specifying and installing these products.

Factors Affecting Weight Per Square Foot

1. Material The choice of material is one of the most significant factors affecting the weight of bar grating. Steel grates are typically the heaviest due to the density of the material. Aluminum offers a lightweight alternative but may not provide the same load-bearing capabilities. Fiberglass reinforced plastics (FRP) are even lighter and resistant to corrosive environments, making them suitable for specific applications, especially in marine or chemical industries.

2. Bar Thickness The thickness of the bars directly correlates to the strength and weight of the grating. Thicker bars can support heavier loads and provide added durability but naturally contribute to a higher overall weight per square foot. Conversely, thinner bars will reduce weight but may sacrifice strength.

3. Bar Spacing The spacing between the bars also plays a role in determining the weight per square foot. Grating with closely spaced bars (high density) tends to weigh more than those with wider spacing. While closer spacing offers better coverage and support for smaller items, it may not always be necessary for every application, thus affecting the overall weight.

bar grating weight per square foot

4. Load Classifications Bar grating is classified into different load ratings, from light to heavy-duty. Heavy-duty grating, designed for high-impact areas—such as vehicle traffic surfaces—will naturally have a higher weight due to its design specifications. Understanding these classifications aids in selecting the appropriate type of grating for specific needs.

5. Finish and Coatings Lastly, the type of surface finish or coatings applied to bar grating can affect its weight. Galvanized coatings for corrosion resistance or non-slip finishes may add minimal weight, but it’s a consideration for projects that need to meet certain specifications.

Practical Implications of Bar Grating Weight

Understanding the weight per square foot of bar grating has several practical implications

- Structural Support Accurate calculation of the weight helps ensure that the supporting structure can handle the load without compromising stability. This is particularly important in industrial settings where heavy machinery is prevalent. - Shipping and Handling Knowing the weight is essential for selecting the right transportation method. Heavier grating may require special handling protocols or tools during installation, contributing to labor and time costs.

- Safety Considerations Proper weight distribution reduces the risk of structural failure, which can pose safety hazards for personnel and equipment. Understanding how the weight impacts load distribution is vital for maintaining a safe working environment.

Conclusion

Bar grating is an indispensable structural element in numerous applications, and understanding its weight per square foot is critical for successful implementation. By considering factors such as material, bar thickness, spacing, load classification, and surface coatings, professionals can make informed decisions that align with safety, performance, and budgetary constraints. In an industry where precision and safety are paramount, a thorough understanding of bar grating's weight and its implications cannot be overstressed.

-

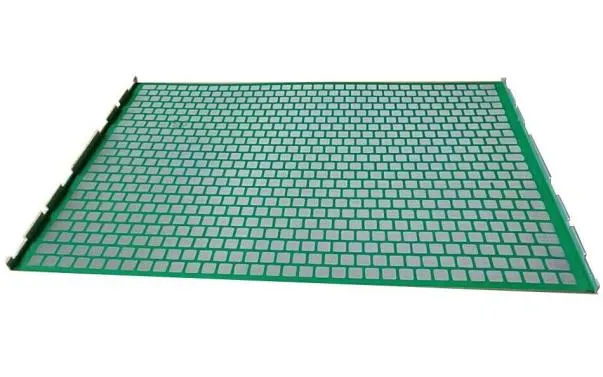

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024