- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Calculating the Weight of Bar Gratings for Structural Applications and Design Considerations

Understanding Bar Grating Weight Factors and Considerations

Bar grating, a metal framework used in various industrial and architectural applications, is widely acknowledged for its strength and versatility. Commonly used in flooring, walkways, and drainage covers, bar grating is not only vital for safety and functionality but also poses specific weight considerations that engineers, architects, and construction professionals need to account for when designing structures.

What is Bar Grating?

Bar grating is composed of a series of parallel bars that are joined together by perpendicular supports. The bars can be made from different materials, including steel, aluminum, and fiberglass, each offering unique properties and advantages. The choice of material significantly affects the weight of the grating. For instance, steel bar grating tends to be much heavier than its aluminum counterpart but offers remarkably high strength, making it suitable for heavy-duty applications.

Factors Affecting Weight

The weight of bar grating is influenced by several factors, including material type, bar spacing, bar height, and load considerations

.1. Material Type As mentioned earlier, the choice of material directly impacts the weight. Steel, being denser than aluminum, will inherently result in a heavier grating. Additionally, while fiberglass is lighter and resistant to corrosion, it may not always provide the same load-bearing capabilities as metal options.

2. Bar Spacing The distance between the bars in a grating system (bar spacing) also plays a critical role in determining weight. Narrower spacing means more bars are used, which adds to the overall weight. Conversely, wider spacing can reduce weight, but it may compromise safety and load capacity.

3. Bar Height Taller bars can increase the weight but may improve load capacity. The balance between height and spacing must be carefully considered in relation to the intended application. For instance, a grating used in a pedestrian walkway will likely have different specifications than that used for heavy machinery access.

4. Load Considerations Depending on the intended use, the load-bearing requirements will necessitate specific design choices that can influence weight. Grating designed to support heavy loads must be constructed with sturdier materials and dimensions, thereby increasing its weight.

bar grating weight

Importance of Weight Calculation

Correct calculations of bar grating weight are imperative for ensuring structural integrity and safety. Engineers use weight figures to determine the support structures required beneath the grating and assess whether existing frameworks can accommodate the additional load. An understudied weight contribution could lead to structural failure, resulting in safety hazards and costly repairs.

Applications and Their Weight Considerations

Bar grating finds application across various sectors, including industrial flooring, platforms, drainage systems, and security enclosures.

- Industrial Flooring In factories or warehouses where heavy machinery operates, grating must be robust enough to bear significant weights. The increased weight of steel grating is often preferred in these environments.

- Walkways and Platforms For pedestrian applications, lighter materials like aluminum may be favored due to ease of installation and reduced load on underlying structures. The weight must still provide adequate safety without becoming cumbersome.

- Drains and Grates The weight of grating used in drainage holes is also essential. It needs to be heavy enough to resist being moved by traffic but designed to allow for efficient water flow.

Conclusion

In conclusion, understanding the weight of bar grating is crucial for its effective application in various industries. It is a multifaceted consideration that impacts safety, cost, and structural planning. By carefully evaluating factors such as material type, bar spacing, bar height, and load requirements, professionals can select the appropriate bar grating for their specific needs. As the demand for more efficient and durable materials continues to rise, so too does the importance of precise calculations regarding the weight of bar grating. Whether for industrial use or architectural design, making informed choices about bar grating will lead to safer and more effective outcomes.

-

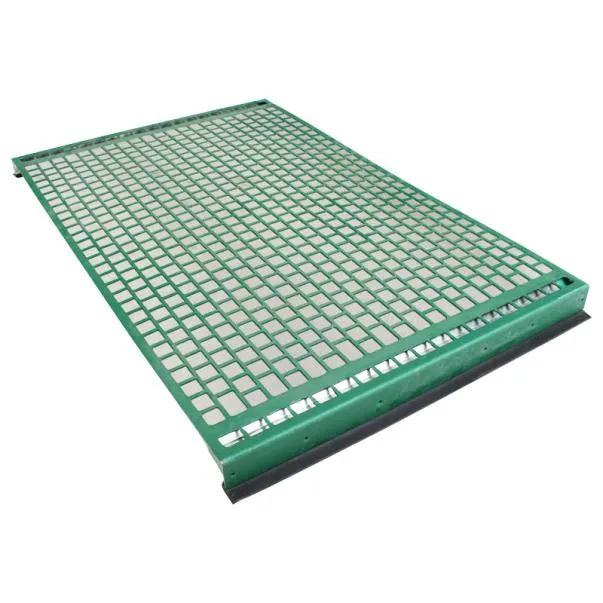

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024