- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

bar grating suppliers

Overview of Bar Grating Suppliers

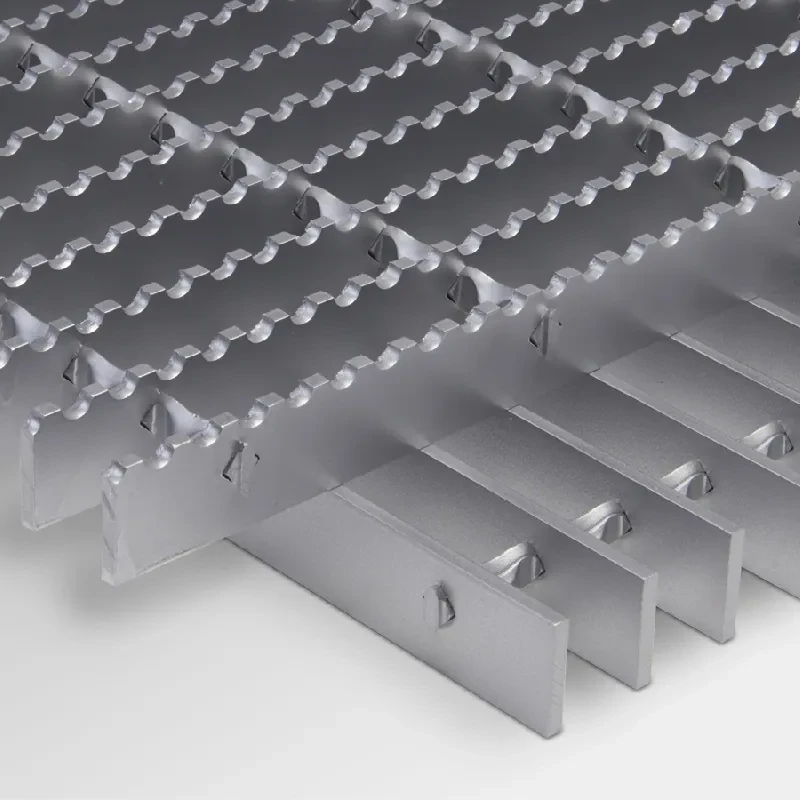

Bar grating is an essential product widely used in various industrial and commercial applications, providing safety, durability, and functionality. As a popular choice for flooring, walkways, and drainage systems, bar grating suppliers play a significant role in ensuring the availability of high-quality materials to meet the diverse needs of their clients. This article explores the importance of bar grating, the types available, and what to consider when choosing a supplier.

What is Bar Grating?

Bar grating is a form of open grid metal flooring made from steel, aluminum, or fiberglass. It consists of load-bearing bars that are welded or locked in place at regular intervals, resulting in a grid-like structure that is highly stable yet allows for water drainage and light penetration. This feature makes it ideal for industrial facilities, commercial buildings, and outdoor environments where safety and accessibility are critical.

Types of Bar Grating

Bar grating comes in various types, tailored to specific applications. The most common materials include

1. Steel Grating Steel is the most frequently used material due to its strength and durability. It is particularly suitable for heavy-duty applications, such as industrial platforms and machine bases. 2. Aluminum Grating Lightweight yet robust, aluminum grating is resistant to corrosion, making it an ideal choice for environments exposed to moisture, like wastewater treatment facilities.

3. Fiberglass Grating This non-metallic option is known for its chemical resistance and lightweight properties. It is commonly used in corrosive environments and where electrical conductivity is a concern.

Choosing the Right Supplier

bar grating suppliers

Selecting a reliable bar grating supplier is crucial for ensuring the quality and performance of the products you choose. Here are several factors to consider when making your selection

1. Reputation Look for suppliers with a proven track record in the industry. Read reviews, check testimonials, and confirm their experience with the specific type of bar grating you need.

2. Product Range A good supplier should offer a variety of materials and styles. Depending on your project requirements, you may need different specifications, such as load ratings, spacing, and finishes.

3. Customization Options Many projects require custom dimensions or designs. Choose a supplier that offers custom fabrication services so that you can get exactly what you need for your application.

4. Customer Service Excellent customer service is vital for a positive purchasing experience. Suppliers should be knowledgeable, responsive, and willing to provide assistance throughout the selection and ordering process.

5. Pricing and Delivery Compare pricing among suppliers but be wary of options that seem unusually low, as this could reflect lower quality. Additionally, inquire about lead times and delivery options to ensure your project timelines are met.

Conclusion

Bar grating suppliers play a crucial role in providing the necessary materials for a variety of applications across different industries. By understanding the types of bar grating available and taking the time to choose the right supplier, businesses can ensure they receive the quality they need for safety and functionality in their projects. With careful consideration, organizations can successfully leverage the benefits of bar grating to enhance their operations and meet stringent safety standards.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024