- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

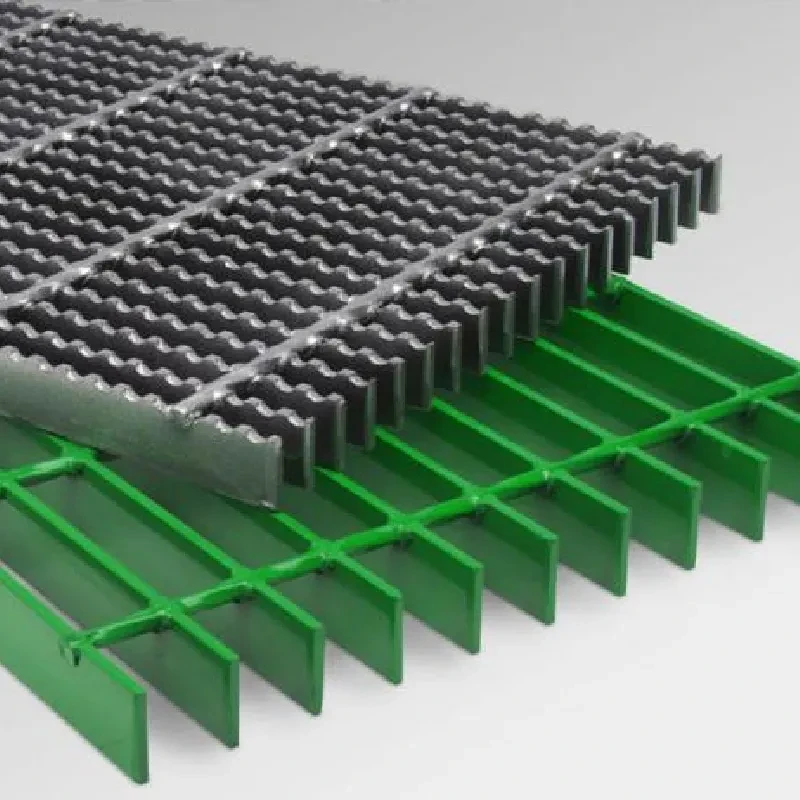

Innovative Bar Grating Platform for Enhanced Structural Support and Safety Performance

The Bar Grating Platform A Versatile Solution for Modern Applications

In today's industrial landscape, the demand for versatile, durable, and efficient solutions is ever-increasing. One such innovation that meets these criteria is the bar grating platform. Widely used across various industries, bar grating platforms offer a unique combination of strength, durability, and lightweight characteristics that make them ideal for a variety of applications.

Bar grating, often made from materials such as steel, aluminum, or fiberglass, consists of a series of parallel bars joined together with perpendicular support bars. This design allows for excellent load-bearing capacities while ensuring that the platform remains lightweight and easy to handle. The open-grid design not only contributes to strength but also facilitates drainage, airflow, and light penetration, making bar grating platforms suitable for both indoor and outdoor environments.

Applications Across Industries

Bar grating platforms are versatile, finding applications in numerous sectors including food processing, manufacturing, construction, and transportation. In the food processing industry, for instance, these platforms are commonly used as flooring in areas where hygiene is critical. The open design allows for easy cleaning and reduces the accumulation of debris, which is vital for maintaining sanitary conditions. Furthermore, their resistance to corrosion and ability to withstand harsh cleaning chemicals contribute to their longevity in food-related applications.

In manufacturing settings, bar grating platforms are utilized as walkways, work surfaces, and as structural supports for various machinery

. Their load-bearing capabilities allow for safe passage of operators and equipment, minimizing the risk of accidents and improving overall workplace safety. In construction, they serve as temporary or permanent structural elements, providing reliable support for workers and materials on sites where traditional solid flooring would be inadequate.Durability and Maintenance

bar grating platform

One of the standout features of bar grating platforms is their durability. Whether made from steel, which offers high strength and toughness, or fiberglass, known for its resistance to corrosion and chemicals, these platforms are built to withstand the rigors of industrial environments. The choice of material often depends on the specific needs of the application. For example, aluminum grates are lightweight and resistant to corrosion, making them ideal for areas prone to moisture. In contrast, steel grating is typically used in heavy load applications due to its strength.

Maintenance of bar grating platforms is generally straightforward. Regular inspections should be conducted to check for signs of wear, especially in high-traffic areas. Cleaning can be done with standard industrial cleaners or pressure washing, depending on the build-up of contaminants. The longevity of these platforms significantly reduces the need for frequent replacements, offering cost-effective solutions over time.

Design Flexibility

Another significant advantage of bar grating platforms is their design flexibility. They can be customized to meet specific requirements in terms of size, load capacity, and material selection. This allows for tailored solutions that can accommodate unique operational needs. Additionally, bar grating can be made in various patterns and spacing configurations, allowing for increased versatility in design, which enhances functionality for different uses.

Conclusion

In conclusion, bar grating platforms represent a remarkable advancement in both safety and efficiency for a myriad of applications across industries. With their robust construction, ease of maintenance, and design flexibility, these platforms provide an ideal solution for businesses seeking to enhance their operational capabilities. As industries continue to evolve and adapt to new challenges, the role of bar grating platforms will undoubtedly become more integral in supporting sustainable and effective practices in the workplace. As a result, they remain a staple in modern industrial design, paving the way for enhanced safety, productivity, and efficiency across the board.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024