- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Top Manufacturers of High-Quality Bar Grating Solutions for Various Applications

A Comprehensive Overview of Bar Grating Manufacturers

Bar grating is an essential component in various industrial applications, providing strength, durability, and safety in environments ranging from construction sites to chemical processing plants. With a growing demand for these products, numerous bar grating manufacturers have emerged in the market. In this article, we will explore the significance of bar grating, the types available, and what to consider when choosing a manufacturer.

Understanding Bar Grating

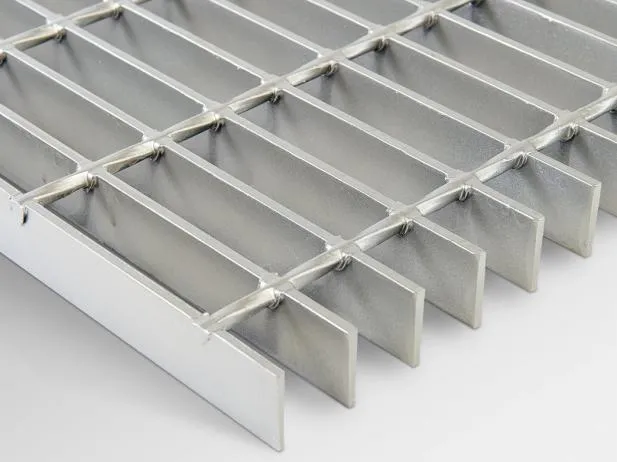

Bar grating is primarily made from metal or fiberglass and consists of a series of parallel bars that are joined by perpendicular cross bars. This construction allows for efficient drainage and ventilation compared to solid surfaces. Bar grating is widely used in platforms, walkways, stair treads, and other structures where both strength and visibility are crucial. It can support heavy loads while ensuring safety for workers and equipment.

Types of Bar Grating

Bar grating comes in various types, each designed for specific applications

1. Steel Bar Grating Often used in industrial settings, steel grating is robust and resistant to heavy loads. It is available in different styles such as welded, pressed, and swaged, each offering unique benefits.

2. Aluminum Bar Grating With a lightweight design, aluminum grating is an excellent choice for situations where rust and corrosion could be a concern. It is commonly used in environments like wastewater treatment and food processing.

3. Fiberglass Bar Grating This non-metallic option is highly resistant to corrosive environments, making it suitable for chemical plants and marine applications. Fiberglass grating is available in several resin types to accommodate different chemical exposures.

4. Plastic Bar Grating Similar to fiberglass, plastic grating is resistant to moisture and chemicals. It is often used in areas requiring slip-resistance, such as swimming pools or wet environments.

bar grating manufacturers

Choosing the Right Manufacturer

When selecting a bar grating manufacturer, several factors should be considered

- Quality Assurance Look for manufacturers that adhere to industry standards and certifications. Quality assurance ensures the product's safety and durability.

- Customization Options Different projects may require specific designs and dimensions. A manufacturer that offers customization can better meet your unique needs.

- Material Selection Ensure the manufacturer provides a range of materials, allowing you to choose based on your specific application requirements.

- Customer Service A responsive and knowledgeable customer service team can significantly enhance your purchasing experience. They can help clarify specifications and provide guidance on the right product for your needs.

- Reputation Researching the manufacturer’s reputation through customer reviews, industry recognition, and referrals can help you make an informed decision.

Conclusion

Bar grating manufacturers play a crucial role in supplying essential materials for various industrial applications. By understanding the types of bar grating available and the factors to consider when choosing a manufacturer, buyers can make informed decisions that ensure safety and efficacy in their projects. Investing in high-quality bar grating from a reputable manufacturer not only enhances structural integrity but also contributes to a safer working environment.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024