- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 08, 2025 03:02

Back to list

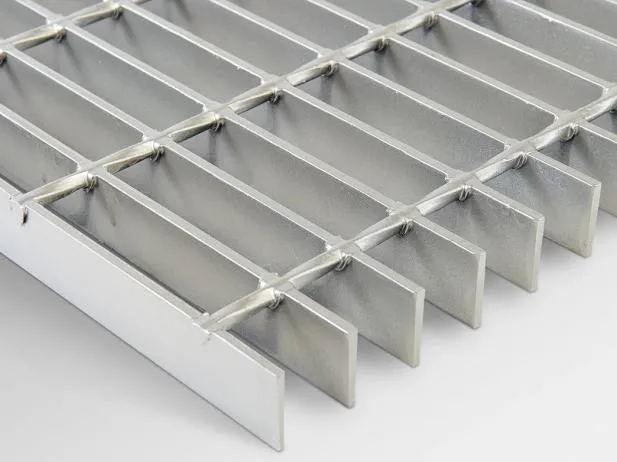

bar grates

Bar grates are an integral component in numerous industrial and architectural applications, serving both practical and aesthetic functions. With an extensive range of designs and materials available, bar grates are engineered to meet the demanding needs of various environments while ensuring safety, durability, and aesthetic appeal. This article delves into the multifaceted world of bar grates, examining their applications, benefits, and considerations for selection.

Maintenance of bar grates is relatively straightforward but crucial for ensuring longevity and safety. Regular inspections for signs of wear, corrosion, or displacement can prevent accidents and prolong the life of the grating. Cleaning is generally simple; depending on the material, grates can be hosed down or brushed to remove debris and buildup. In more demanding conditions, specific cleaning agents can be employed to maintain the pristine condition of the grates, particularly stainless steel variants. For architects and engineers, integrating bar grates into designs offers an opportunity to marry functionality with design. Custom grate designs can be fabricated to follow specific curves, patterns, and finishes, enhancing the aesthetic appeal of a space while fulfilling practical needs. This customization capability makes bar grates a versatile choice for unique or challenging projects that demand both innovative design and reliable performance. In the procurement of bar grates, it’s imperative to partner with reputable manufacturers with proven track records of quality and service. Checking credentials, industry certifications, and past project portfolios can provide insight into a manufacturer's expertise and reliability. Moreover, engaging with manufacturers who offer comprehensive support and consultation can greatly assist in selecting and integrating the right bar grate solution for your specific needs. In conclusion, bar grates are more than just flooring solutions; they are essential elements that contribute to the safety, durability, and aesthetics of a space. Understanding the types, materials, application benefits, and maintenance requirements of bar grates positions businesses and designers to make informed decisions that enhance operational efficiencies and elevate environmental aesthetics. Embracing the versatility and utility of bar grates not only meets functional needs but also contributes to creating safe, sustainable, and visually pleasing environments.

Maintenance of bar grates is relatively straightforward but crucial for ensuring longevity and safety. Regular inspections for signs of wear, corrosion, or displacement can prevent accidents and prolong the life of the grating. Cleaning is generally simple; depending on the material, grates can be hosed down or brushed to remove debris and buildup. In more demanding conditions, specific cleaning agents can be employed to maintain the pristine condition of the grates, particularly stainless steel variants. For architects and engineers, integrating bar grates into designs offers an opportunity to marry functionality with design. Custom grate designs can be fabricated to follow specific curves, patterns, and finishes, enhancing the aesthetic appeal of a space while fulfilling practical needs. This customization capability makes bar grates a versatile choice for unique or challenging projects that demand both innovative design and reliable performance. In the procurement of bar grates, it’s imperative to partner with reputable manufacturers with proven track records of quality and service. Checking credentials, industry certifications, and past project portfolios can provide insight into a manufacturer's expertise and reliability. Moreover, engaging with manufacturers who offer comprehensive support and consultation can greatly assist in selecting and integrating the right bar grate solution for your specific needs. In conclusion, bar grates are more than just flooring solutions; they are essential elements that contribute to the safety, durability, and aesthetics of a space. Understanding the types, materials, application benefits, and maintenance requirements of bar grates positions businesses and designers to make informed decisions that enhance operational efficiencies and elevate environmental aesthetics. Embracing the versatility and utility of bar grates not only meets functional needs but also contributes to creating safe, sustainable, and visually pleasing environments.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024