- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 19, 2025 00:33

Back to list

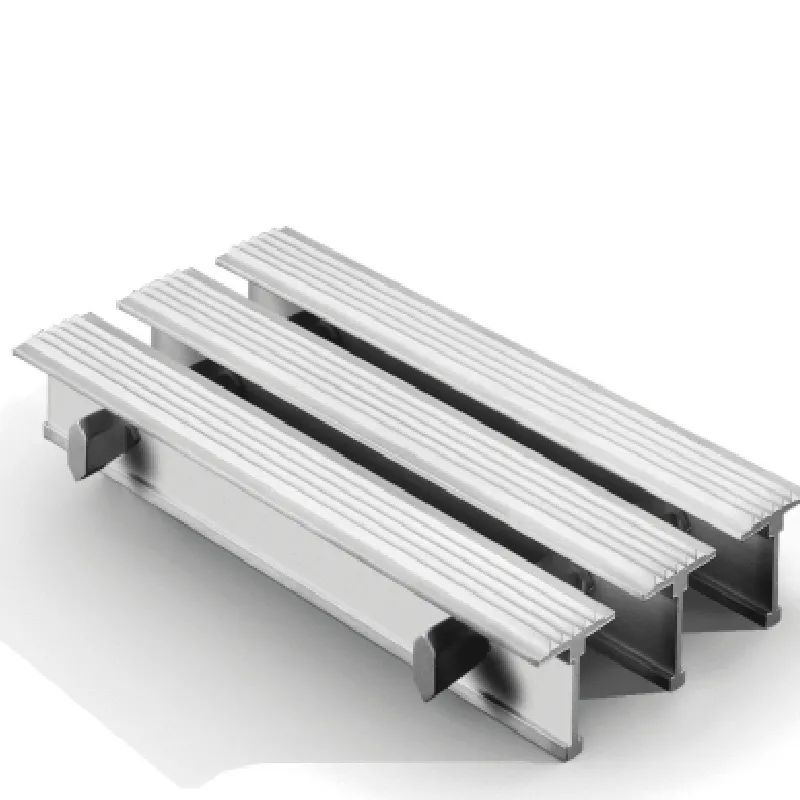

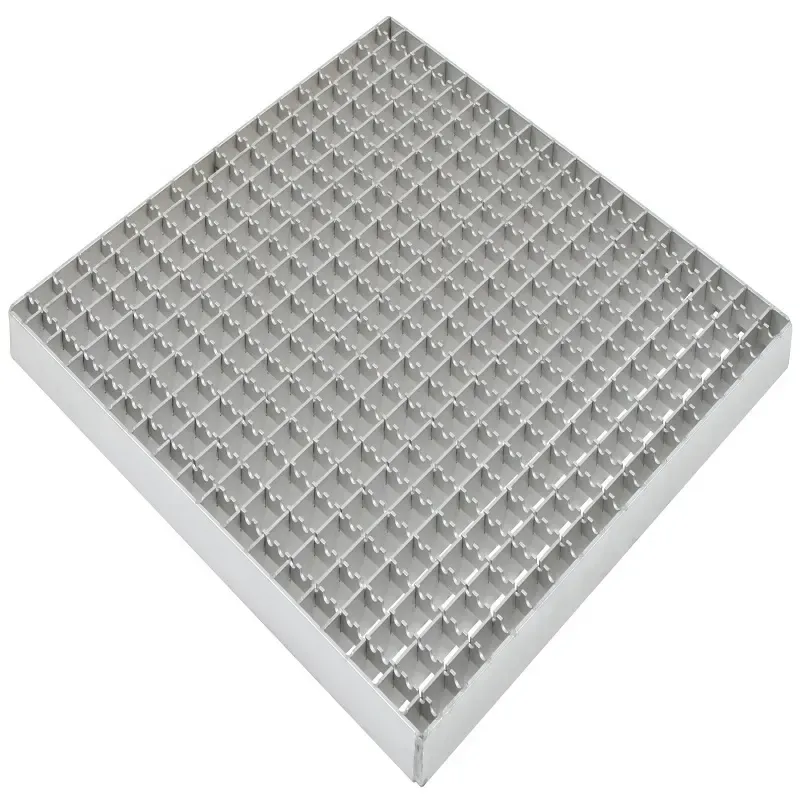

anti slip grating

Safety and durability are paramount in industrial and commercial settings, this is where anti-slip grating plays a pivotal role. With decades of practical application, anti-slip grating has proved to be an irreplaceable solution for preventing slip and fall accidents. This article delves into the unique features, benefits, and applications of anti-slip grating, drawing on real-world experiences and expert insights to provide a comprehensive understanding.

The trustworthiness of anti-slip grating is further reinforced by its successful implementation across various sectors. Facilities managers have expressed confidence in these products' ability to reduce liability and enhance overall workplace safety. Testimonials from satisfied users highlight the peace of mind gained from knowing that every step is secure, even in the most challenging conditions. Additionally, many leading manufacturers offer warranties, further attesting to the product's reliability and the confidence they have in their product offerings. Practical application also reveals that anti-slip grating is not limited to industrial environments. Commercial spaces such as parking structures, public transit facilities, and sports stadiums have adopted these solutions to improve safety for the general public. Architects and builders have praised the aesthetic versatility that these gratings bring, offering both functionality and design flexibility without compromising on safety. Maintenance of anti-slip grating stands out for its simplicity, another appealing factor for businesses. Regular cleaning with standard equipment keeps the grating effective, ensuring long-term performance without extensive upkeep costs. This maintenance efficiency further underscores the economic advantage of choosing anti-slip grating. In conclusion, anti-slip grating is a testament to the blend of practical experience, professional expertise, authoritative standards, and trusted results. Its critical role in preventing accidents, alongside its adaptability and maintenance ease, makes it an invaluable asset across industries. As safety continues to be a top priority, anti-slip grating remains a steadfast solution, backed by user experiences and industry standards. Its contributions to workplace safety and economic efficiency render it a superior choice for businesses seeking to enhance both safety and operational performance.

The trustworthiness of anti-slip grating is further reinforced by its successful implementation across various sectors. Facilities managers have expressed confidence in these products' ability to reduce liability and enhance overall workplace safety. Testimonials from satisfied users highlight the peace of mind gained from knowing that every step is secure, even in the most challenging conditions. Additionally, many leading manufacturers offer warranties, further attesting to the product's reliability and the confidence they have in their product offerings. Practical application also reveals that anti-slip grating is not limited to industrial environments. Commercial spaces such as parking structures, public transit facilities, and sports stadiums have adopted these solutions to improve safety for the general public. Architects and builders have praised the aesthetic versatility that these gratings bring, offering both functionality and design flexibility without compromising on safety. Maintenance of anti-slip grating stands out for its simplicity, another appealing factor for businesses. Regular cleaning with standard equipment keeps the grating effective, ensuring long-term performance without extensive upkeep costs. This maintenance efficiency further underscores the economic advantage of choosing anti-slip grating. In conclusion, anti-slip grating is a testament to the blend of practical experience, professional expertise, authoritative standards, and trusted results. Its critical role in preventing accidents, alongside its adaptability and maintenance ease, makes it an invaluable asset across industries. As safety continues to be a top priority, anti-slip grating remains a steadfast solution, backed by user experiences and industry standards. Its contributions to workplace safety and economic efficiency render it a superior choice for businesses seeking to enhance both safety and operational performance.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024