- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Calculating the Weight of Aluminum Grating for Construction and Design Applications

Understanding Aluminum Grating Weight Key Factors and Calculations

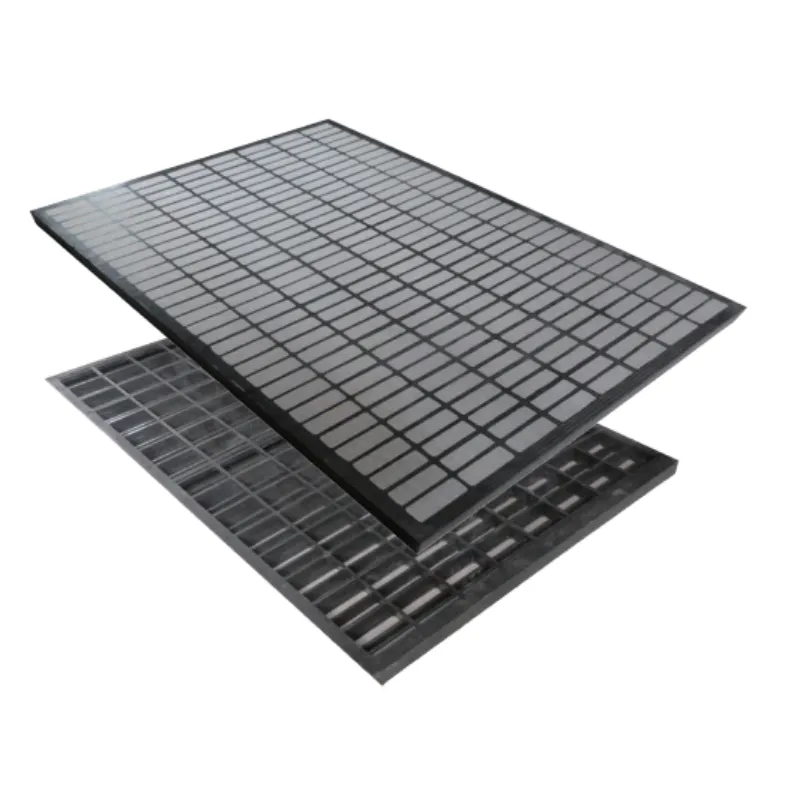

Aluminum grating has become a popular choice for various industrial and commercial applications due to its strength, durability, and lightweight nature. Understanding the weight of aluminum grating is crucial for engineers, architects, and construction professionals as it directly impacts design choices, load-bearing capacities, and installation processes. In this article, we will explore the factors that influence aluminum grating weight, how to calculate it, and its applications.

Factors Influencing Aluminum Grating Weight

Several factors determine the weight of aluminum grating

1. Material Composition Aluminum is available in various alloys, each with different properties and densities. The most commonly used aluminum alloy for grating is 6061, which provides a good balance between strength and weight.

2. Grating Type Aluminum grating can be designed in different styles, including welded, riveted, and bolted types. The design choice affects the material used and, consequently, the weight. For example, welded gratings tend to be heavier than their riveted counterparts due to the additional material used in the welding process.

3. Dimensions Length, width, and height significantly influence the weight of the grating. Thicker bars or larger surface areas will naturally contribute to a higher overall weight. Typically, aluminum grating comes in various standard sizes, which can be customized based on project requirements.

4. Open Area The percentage of open space in the grating design also affects its weight. Gratings with a higher open area ratio will weigh less, as they contain less solid material. This factor is particularly important for applications where light transmission or drainage is required.

5. Surface Treatment Surface finishes, such as anodizing or powder coating, can alter the weight of aluminum grating slightly. While these treatments are primarily for corrosion protection and aesthetics, they may add a marginal amount of weight.

Calculating Aluminum Grating Weight

aluminum grating weight

To calculate the weight of aluminum grating, you need to know its dimensions, the density of the aluminum alloy, and the open area percentage. The following formula can be used

\[ \text{Weight} = \text{Length} \times \text{Width} \times \text{Thickness} \times \text{Density} \times (1 - \text{Open Area Percentage}) \]

Where

- Length Length of the grating in inches or mm - Width Width of the grating in inches or mm - Thickness Thickness of the grating bars - Density of Aluminum Alloy Typically ranges from 2.6 to 2.8 g/cm³ for common aluminum alloys - Open Area Percentage Expressed as a decimal (e.g., 0.4 for 40% open area)

Using these measurements will give you the total weight of the aluminum grating, enabling better planning and execution of projects.

Applications of Aluminum Grating

Aluminum grating is widely used in various sectors, including

- Industries As walkways, platforms, and catwalks in factories and warehouses. Its lightweight nature allows for easier transportation and quicker installation. - Construction For stair treads, decking, and railings, providing both safety and aesthetic appeal. - Infrastructure In drainage covers and trench covers, where the open area is crucial for water flow. - Transportation In the design of buses, trains, and other vehicles, where weight savings can contribute to fuel efficiency.

Conclusion

In summary, understanding the weight of aluminum grating involves various factors, including material properties, design choices, and dimensions. By accurately calculating the weight using the appropriate formulas, professionals can ensure that their projects meet safety and efficiency standards. The versatility and lightweight nature of aluminum grating make it an invaluable component in modern construction and industrial applications. Whether for structural integrity or aesthetic purposes, aluminum grating continues to be a material of choice in various settings.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024