- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 06:19

Back to list

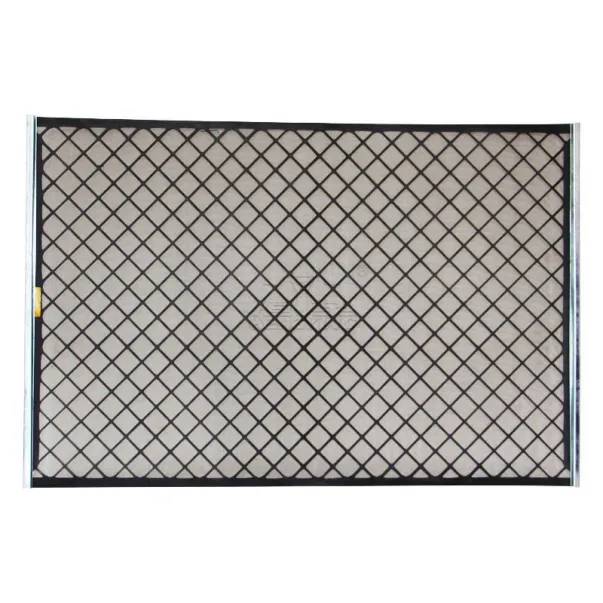

Offshore Pipeline Counterweight Welded Wire Mesh

Aluminum grating, a popular product in industrial and architectural spaces, owes its prevalence to its blend of durability and weight efficiency. For engineers, architects, and procurement managers looking to strike a balance between strength and weight, understanding the aluminum grating weight is crucial for decision-making.

To provide an authoritative and trustworthy view, consider the factors impacting aluminum grating weight. The weight of a specific aluminum grating product is determined by its bar size, spacing, and overall design pattern. For instance, close mesh aluminum grating, though slightly heavier due to increased material use, offers enhanced load-bearing capabilities and is often chosen for areas with heavy pedestrian traffic or sensitive operations. Expertise in material science reveals that despite the light weight, aluminum grating remains resistant to corrosion. This property is particularly beneficial in wet or corrosive environments, where material longevity is as critical as weight. Industries that require stringent hygiene standards, such as food processing, also favor aluminum grating for its ease of cleaning and non-toxic properties. Real-world experience from industry professionals demonstrates further benefits of aluminum grating weight efficiency. For example, a project in the offshore oil industry noted a 30% reduction in project costs attributed to lighter grating, which facilitated faster construction timelines and reduced foundation stress. In conclusion, while the aluminum grating weight might seem like a simple specification detail, it is a pivotal aspect in material selection that affects cost efficiency, design flexibility, and project sustainability. This combination of lightweight strength and corrosion resistance positions aluminum grating as a strategic choice for a wide range of applications. Engineers and architects committed to sustainable and cost-effective solutions can rely on aluminum grating to deliver a balanced performance without compromise.

To provide an authoritative and trustworthy view, consider the factors impacting aluminum grating weight. The weight of a specific aluminum grating product is determined by its bar size, spacing, and overall design pattern. For instance, close mesh aluminum grating, though slightly heavier due to increased material use, offers enhanced load-bearing capabilities and is often chosen for areas with heavy pedestrian traffic or sensitive operations. Expertise in material science reveals that despite the light weight, aluminum grating remains resistant to corrosion. This property is particularly beneficial in wet or corrosive environments, where material longevity is as critical as weight. Industries that require stringent hygiene standards, such as food processing, also favor aluminum grating for its ease of cleaning and non-toxic properties. Real-world experience from industry professionals demonstrates further benefits of aluminum grating weight efficiency. For example, a project in the offshore oil industry noted a 30% reduction in project costs attributed to lighter grating, which facilitated faster construction timelines and reduced foundation stress. In conclusion, while the aluminum grating weight might seem like a simple specification detail, it is a pivotal aspect in material selection that affects cost efficiency, design flexibility, and project sustainability. This combination of lightweight strength and corrosion resistance positions aluminum grating as a strategic choice for a wide range of applications. Engineers and architects committed to sustainable and cost-effective solutions can rely on aluminum grating to deliver a balanced performance without compromise.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024