- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 07:36

Back to list

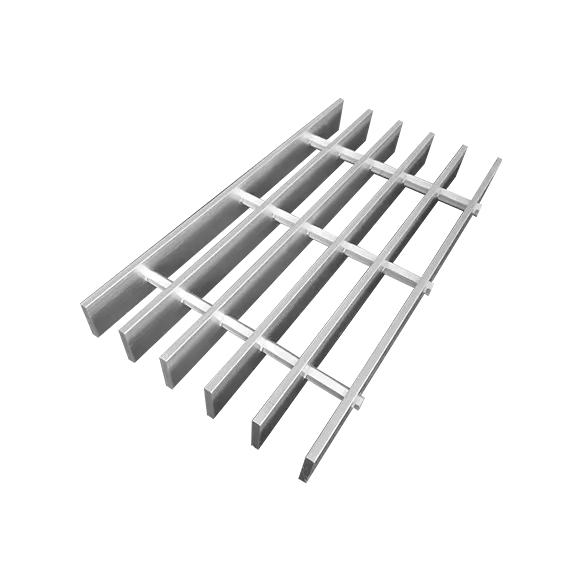

Steel Grating

Aluminum grating is an essential component in various industries, known for its lightweight properties, corrosion resistance, and excellent strength-to-weight ratio. These attributes make it an indispensable choice for architects and engineers, especially in sectors like construction, transportation, and utilities.

Additionally, the load capacity is a critical specification. It determines the maximum weight the grating can safely support and is generally specified as a uniform load per square foot or concentrated load (e.g., a point load at mid-span). Engineers should consult manufacturer load tables or conduct a detailed analysis to ensure compliance with safety standards and prevent failure. Installation practices also play a vital role in the performance of aluminum gratings. Proper anchoring, correct use of fasteners, and adherence to manufacturer guidelines ensure stability and extend the lifespan of the grating. Incorrect installation can lead to grating failure, posing significant safety risks. Maintenance requirements should not be overlooked. Although aluminum requires minimal maintenance due to its corrosion-resistant nature, regular inspections and cleaning can identify potential issues early and prolong the service life. In environments with high debris accumulation, ensuring clear passage through the grating is critical to maintaining its load-bearing capabilities. Moreover, environmental considerations are becoming increasingly important. Aluminum is a sustainable choice due to its recyclability. Companies opting for aluminum grating contribute to a reduced environmental footprint, aligning with modern sustainable development goals. In conclusion, understanding aluminum grating specifications involves a comprehensive analysis of material type, design features, and environmental factors. By prioritizing these aspects, stakeholders can ensure that their choice of aluminum grating meets performance demands while aligning with industry standards and sustainability goals. This informed approach enhances both the safety and efficacy of infrastructure projects where aluminum gratings are utilized.

Additionally, the load capacity is a critical specification. It determines the maximum weight the grating can safely support and is generally specified as a uniform load per square foot or concentrated load (e.g., a point load at mid-span). Engineers should consult manufacturer load tables or conduct a detailed analysis to ensure compliance with safety standards and prevent failure. Installation practices also play a vital role in the performance of aluminum gratings. Proper anchoring, correct use of fasteners, and adherence to manufacturer guidelines ensure stability and extend the lifespan of the grating. Incorrect installation can lead to grating failure, posing significant safety risks. Maintenance requirements should not be overlooked. Although aluminum requires minimal maintenance due to its corrosion-resistant nature, regular inspections and cleaning can identify potential issues early and prolong the service life. In environments with high debris accumulation, ensuring clear passage through the grating is critical to maintaining its load-bearing capabilities. Moreover, environmental considerations are becoming increasingly important. Aluminum is a sustainable choice due to its recyclability. Companies opting for aluminum grating contribute to a reduced environmental footprint, aligning with modern sustainable development goals. In conclusion, understanding aluminum grating specifications involves a comprehensive analysis of material type, design features, and environmental factors. By prioritizing these aspects, stakeholders can ensure that their choice of aluminum grating meets performance demands while aligning with industry standards and sustainability goals. This informed approach enhances both the safety and efficacy of infrastructure projects where aluminum gratings are utilized.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024