- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

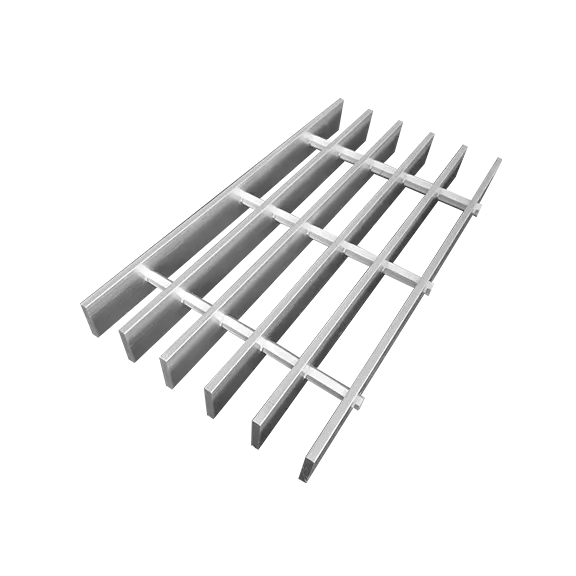

aluminum grating specifications

Aluminum Grating Specifications An Overview

Aluminum grating has become an essential component in various construction and industrial applications thanks to its lightweight, durable, and corrosion-resistant properties. This article provides a comprehensive overview of aluminum grating specifications, discussing its design, manufacturing standards, and various applications.

What is Aluminum Grating?

Aluminum grating is a type of flooring material made from aluminum that consists of a series of parallel bars or plates, which are connected by welded or bolted cross members. This design allows for superior load-bearing capacity while providing ventilation, drainage, and slip resistance. It is commonly used in walkways, platforms, and other structural applications where strength and safety are paramount.

Key Specifications

When considering aluminum grating for a project, it is crucial to understand its specifications, which typically include material grade, load capacity, bar spacing, and surface treatment.

1. Material Grade Aluminum grating is primarily made from aluminum alloy 6061 or 6063. Alloy 6061 is known for its excellent strength-to-weight ratio, corrosion resistance, and weldability, making it ideal for industrial use. Alloy 6063, while slightly less durable, provides better finish and extrudability, often used in architectural applications.

2. Load Capacity Load capacity is a critical specification, determined by factors such as the size and spacing of the bars and the type of application. Common loading classes include light, medium, and heavy-duty. The American National Standards Institute (ANSI) and the Aluminum Association provide guidelines for determining load capacities based on expected foot traffic and the nature of the services being conducted on the grating.

aluminum grating specifications

3. Bar Spacing The spacing between the bars also affects load distribution and safety. Typical bar spacing ranges from 1 inch to 1 ½ inches, allowing for adequate drainage while ensuring stability underfoot. The spacing should be chosen in accordance with the intended application to prevent objects from falling through and to maintain user safety.

4. Surface Treatment To enhance performance, aluminum grating can undergo surface treatments like anodizing or powder coating. Anodizing not only increases corrosion resistance but also adds durability and aesthetic appeal by providing a hard protective layer. Powder coating offers various color options, making it suitable for areas where aesthetics are important while also delivering excellent weather resistance.

Applications of Aluminum Grating

Aluminum grating finds application in several industries, including

- Industrial Facilities Used in factories and production sites for walkways, platforms, machine guarding, and drainage systems. - Transportation Find applications in railway stations, airports, and bus terminals as flooring materials for pedestrian areas. - Architectural Uses Frequently employed in architectural designs to create visually appealing facades, railings, and stair treads. - Marine Environments Due to its corrosion resistance, aluminum grating is ideal for marine applications, including docks and piers.

Conclusion

In summary, aluminum grating is a versatile and robust solution for various construction and industrial needs. Understanding its specifications, including material grade, load capacity, bar spacing, and surface treatment, is essential for selecting the appropriate type for your application. With its combination of durability and aesthetic potential, aluminum grating continues to be a top choice in both industrial and architectural markets. Investing in high-quality aluminum grating ensures safety, performance, and longevity in any project.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024