- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

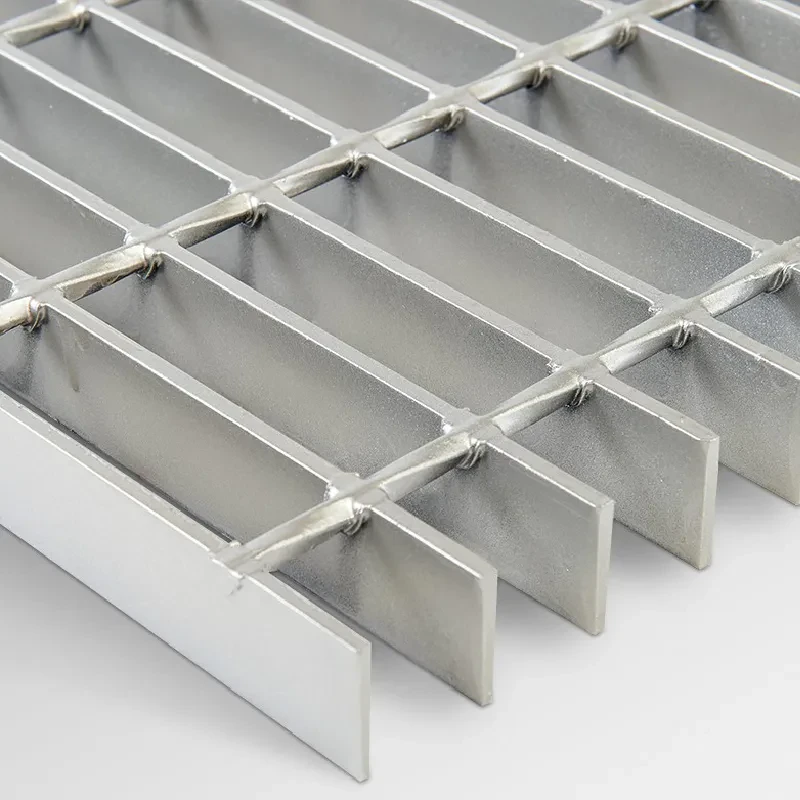

Specifications for Aluminum Grating Material and Performance Standards for Structural Applications

Understanding Aluminum Grating Specifications

Aluminum grating is an essential component used across various industries, offering both structural support and safety features. Its specifications dictate the quality, durability, and suitability for specific applications. By understanding these specifications, engineers and project managers can select the most appropriate aluminum grating for their needs.

Definition and Purpose

Aluminum grating is a type of flooring or platform made from aluminum bars that are arranged in a grid pattern. This design allows for drainage of liquids and provides excellent slip resistance, making it ideal for industrial environments, walkways, and platforms. The lightweight nature of aluminum makes it easier to handle and install compared to heavier materials like steel or fiberglass.

Key Specifications

1. Material Grade The most common aluminum alloys used in grating are 6061 and 6063. These alloys have been treated for strength and corrosion resistance, making them suitable for outdoor and high-humidity applications. Understanding the material grade is crucial for determining the grating's load-bearing capacity and longevity.

2. Load Capacity Load capacity refers to the amount of weight that the grating can support without failure. It’s categorized into several types, including pedestrian loads (for walkways) and heavier industrial loads (for machinery and equipment). Specifications often include standard load tables which help in calculating the appropriate grating for specific applications.

3. Bar Spacing and Dimensions The spacing between bars, typically measured in inches, affects both the strength and safety of the grating. Common dimensions include a bar thickness of 1 inch or more and spacing ranging from 1 inch to 2 inches apart. Compliance with standards such as the Americans with Disabilities Act (ADA) is imperative in ensuring safety for all users.

aluminum grating specifications

4. Anti-Slip Features Many aluminum gratings come with anti-slip finishes including extruded surfaces or punched holes, which improve traction. These features are crucial in environments that may become wet or greasy, mitigating the risk of slips and falls.

5. Coatings and Finishes Aluminum grating can be anodized or painted to enhance corrosion resistance. Anodized finishes involve an electrochemical process that thickens the naturally occurring oxide layer on the aluminum surface, providing a durable and aesthetically pleasing finish. On the other hand, powder coating offers a wide range of colors and additional protection against environmental wear.

6. Installation Options Aluminum grating can be installed using several methods including bolting, welding, or using mounting clips. Each method has its own advantages and limitations, depending on the application requirements and surface conditions. Understanding the installation specifics is crucial for maximizing the grating’s performance and safety.

Applications of Aluminum Grating

Aluminum grating is widely used in various applications such as

- Industrial Facilities For walkways, platforms, and stair treads, providing safety and accessibility in manufacturing plants. - Water Treatment Facilities The corrosion-resistant nature of aluminum makes it ideal for environments with high moisture and chemical exposure. - Marine Applications Used for docks and boat ramps, where lightweight materials are essential for ease of use and installation. - Architectural Applications Providing aesthetic solutions for exteriors and interiors, aluminum grating can be utilized in decorative screens and ventilation solutions.

Conclusion

Selecting the right aluminum grating requires a comprehensive understanding of its specifications. By considering material grade, load capacity, dimensions, anti-slip features, coatings, and installation options, you can ensure that you select a product that meets the demands of your specific application. With its inherent properties of strength, durability, and resistance to corrosion, aluminum grating remains a preferred choice in various sectors, promoting safety and functionality in engineering and design.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024