- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

aluminum grating price

Understanding the Pricing of Aluminum Grating

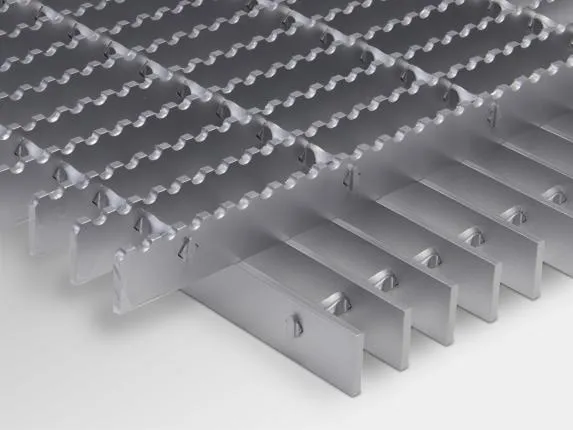

Aluminum grating has become an increasingly popular material in various industries due to its lightweight, durability, and excellent properties. Its applications range from industrial flooring and walkways to stair treads and drainage covers. However, one of the critical factors that both manufacturers and consumers must consider is the price of aluminum grating.

Factors Influencing the Price of Aluminum Grating

The price of aluminum grating can vary significantly based on several factors. One of the primary influences is the type of aluminum alloy used in the production. Different alloys offer varying levels of strength, corrosion resistance, and weight, which can all affect the overall cost. For example, alloy 6061, known for its excellent weldability and corrosion resistance, might be priced higher than a lower-grade alloy.

Another crucial factor is the manufacturing process. Aluminum grating can be produced through various methods, such as extrusion or welding. Extruded aluminum grating tends to have a higher production cost due to the complexity of the manufacturing process, while welded grating may be more economical. Additionally, the complexity of the design, including the spacing and overall dimensions, can also impact the price.

Quantity and Customization

aluminum grating price

When considering the price of aluminum grating, the quantity required plays a vital role. Bulk orders generally come with a discount, making it more cost-effective for larger projects. Conversely, smaller orders may incur higher costs per unit due to minimum order requirements or set-up fees in the manufacturing process.

Customization options can further influence pricing. Standard grating sizes and styles may be readily available at a lower cost, while custom designs tailored to specific applications will drive up the price. Factors such as coatings, finishes, and additional features like anti-slip surfaces also contribute to the overall expense.

Market Trends and Costs

The fluctuations in the market for raw materials, particularly aluminum, can significantly affect pricing. Global events, trade policies, and supply chain logistics can lead to price volatility. Additionally, the current demand for construction materials often correlates with aluminum prices. For instance, during a construction boom, the demand for aluminum products, including grating, may rise, leading to higher prices.

Conclusion

In summary, the price of aluminum grating is determined by a range of factors, including the type of alloy, manufacturing processes, quantity ordered, and customization requirements. For both consumers and businesses, understanding these elements is crucial for budgeting and project planning. While aluminum grating may represent an initial investment, its longevity, low maintenance needs, and structural advantages contribute to its overall value. Whether for industrial use or aesthetic architectural designs, aluminum grating remains a versatile choice that balances functionality and cost. As markets continue to evolve, staying informed about pricing trends can help buyers make the most economical and strategic decisions.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024