- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

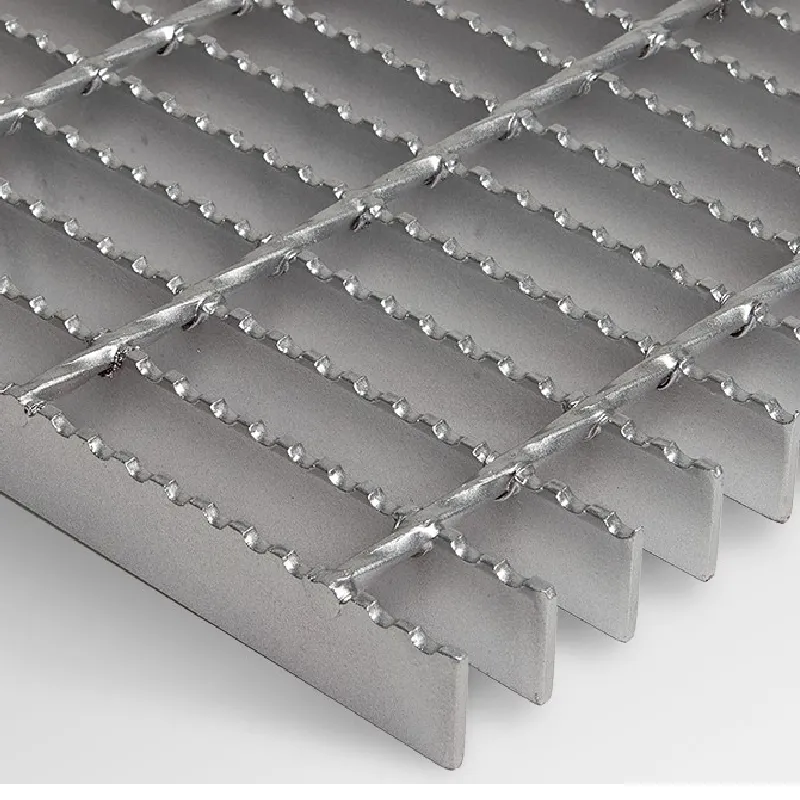

Leading Manufacturers of Durable Aluminum Grating for Various Industrial Applications

The Rise of Aluminum Grating Manufacturers

In the realm of industrial construction and architectural design, aluminum grating has emerged as a crucial component, combining functionality with aesthetic appeal. As the demand for durable, lightweight, and corrosion-resistant materials grows, aluminum grating manufacturers are playing an increasingly significant role in various sectors, from wastewater treatment and petrochemical plants to commercial and residential construction.

Aluminum grating is favored for its remarkable properties. Unlike traditional steel grating, aluminum does not rust, making it ideal for environments where exposure to water and chemicals is common. This corrosion resistance significantly extends the life of the grating, reducing maintenance costs and enhancing safety. Moreover, aluminum is lightweight compared to steel, which simplifies installation and reduces transportation costs. Given these advantages, manufacturers are witnessing a surge in demand for aluminum grating products.

The manufacturing process of aluminum grating involves several steps, including extrusion, fabrication, and surface treatment. Extrusion is a method where aluminum is pressed through a die to create long, continuous shapes. This process allows for the production of grating with various bearing bar depths and spacing, which can be tailored to meet specific load requirements. After extrusion, manufacturers can further fabricate the grating by cutting it to specific dimensions or adding holes for drainage and airflow, enhancing its functionality.

Surface treatment is another essential aspect of aluminum grating manufacturing. Commonly, anodization is applied, which not only improves the appearance of aluminum but also enhances its corrosion resistance. This process forms a protective oxide layer on the surface, guarding against scratches and environmental wear. Other treatments, such as powder coating, can be used to provide additional color and finish options, catering to aesthetic preferences in architectural applications.

aluminum grating manufacturers

The adaptability of aluminum grating has led to its utilization in a myriad of installations. In industrial settings, it is commonly used for walkways, platforms, and stair treads, providing secure footing while enabling the passage of light and air. In commercial spaces, aluminum grating can be designed for decorative purposes, enhancing the visual appeal of lobbies and outdoor spaces. Its lightweight nature and customizable design make it an attractive option for architects and builders seeking innovative solutions.

The competitive landscape for aluminum grating manufacturers is evolving. Companies are increasingly focusing on sustainability practices, recognizing the environmental impact of their production processes. Many are investing in recycling initiatives, sourcing aluminum from recycled materials to minimize waste and reduce their carbon footprint.

As the construction and industrial sectors continue to embrace sustainable materials, aluminum grating manufacturers are well-positioned to thrive. With advances in technology and production techniques, these manufacturers are not only meeting current demand but also innovating to create new products that push the boundaries of what aluminum grating can offer.

In conclusion, the growth of aluminum grating manufacturers is indicative of a broader trend towards efficient, sustainable materials in construction and industry. With their combination of durability, aesthetic versatility, and eco-friendliness, aluminum grating products are likely to remain at the forefront of architectural and industrial design for years to come.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024