- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 17, 2025 04:36

Back to list

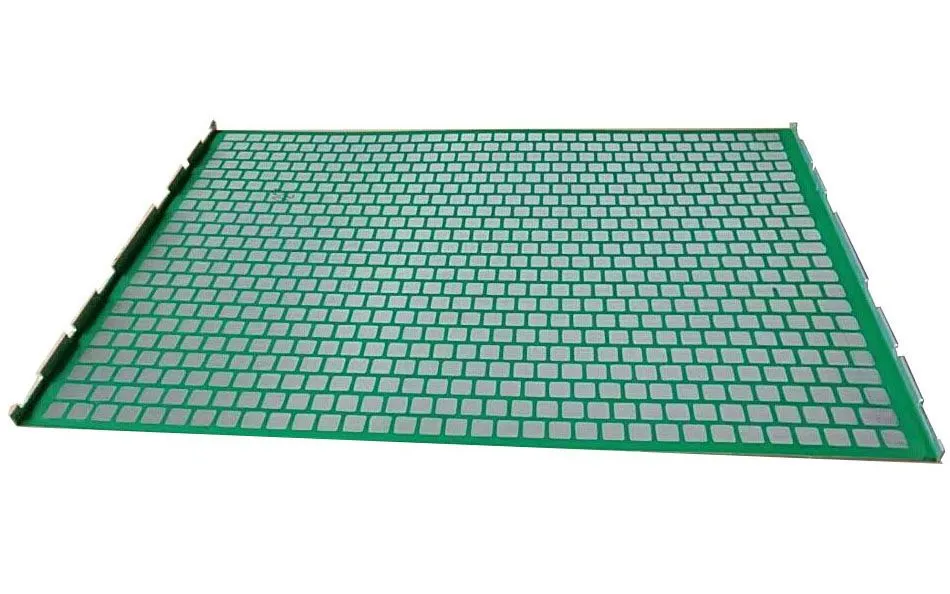

Steel Grating

Aluminum grating has emerged as an essential component in industrial and architectural projects due to its unique combination of light weight, corrosion resistance, and structural strength. With the evolving demands of modern construction, aluminum grating offers a solution that harmonizes functionality with aesthetic appeal.

Trustworthiness in products is paramount, and aluminum grating excels in this regard. The production standards and quality control processes for aluminum grating have been refined to deliver a consistently reliable product. Manufacturers typically subject their grating to rigorous testing, ensuring compliance with international standards for load-bearing capacity and safety. These stringent standards provide assurances to architects, engineers, and builders alike that aluminum grating will perform reliably over time, irrespective of the demands placed upon it. Transparent documentation and certificates often accompany quality aluminum grating, offering peace of mind regarding material integrity and performance specifications. Moreover, sustainability considerations are increasingly influencing material choice in construction, and aluminum grating stands out for its eco-friendly attributes. Aluminum is one of the most recyclable materials available; it can be recycled repeatedly without a loss of quality, significantly reducing its environmental footprint. This aspect appeals to environmentally conscious clients and aligns with the growing trends towards sustainable design and construction practices. A notable case study illustrating aluminum grating's usefulness derives from the use of the material in a large-scale water treatment facility. Here, the grating was selected for its superior corrosion resistance, which ensured operational reliability in a highly corrosive, wet environment. Through this strategic choice, the facility experienced a marked reduction in required maintenance intervals, leading to substantive cost savings and operational efficiencies. This real-world example underscores the material's reliability and aligns with industry trends emphasizing cost-effective, sustainable practices. In conclusion, aluminum grating continues to be a material of choice across various sectors due to its lightweight nature, corrosion resistance, aesthetic flexibility, and sustainability. Its proven track record in diverse applications establishes its credibility, making it a trusted solution among professionals who demand both performance and durability. As industries advance, aluminum grating remains at the forefront, offering innovative solutions that meet the intricate needs of modern construction and design.

Trustworthiness in products is paramount, and aluminum grating excels in this regard. The production standards and quality control processes for aluminum grating have been refined to deliver a consistently reliable product. Manufacturers typically subject their grating to rigorous testing, ensuring compliance with international standards for load-bearing capacity and safety. These stringent standards provide assurances to architects, engineers, and builders alike that aluminum grating will perform reliably over time, irrespective of the demands placed upon it. Transparent documentation and certificates often accompany quality aluminum grating, offering peace of mind regarding material integrity and performance specifications. Moreover, sustainability considerations are increasingly influencing material choice in construction, and aluminum grating stands out for its eco-friendly attributes. Aluminum is one of the most recyclable materials available; it can be recycled repeatedly without a loss of quality, significantly reducing its environmental footprint. This aspect appeals to environmentally conscious clients and aligns with the growing trends towards sustainable design and construction practices. A notable case study illustrating aluminum grating's usefulness derives from the use of the material in a large-scale water treatment facility. Here, the grating was selected for its superior corrosion resistance, which ensured operational reliability in a highly corrosive, wet environment. Through this strategic choice, the facility experienced a marked reduction in required maintenance intervals, leading to substantive cost savings and operational efficiencies. This real-world example underscores the material's reliability and aligns with industry trends emphasizing cost-effective, sustainable practices. In conclusion, aluminum grating continues to be a material of choice across various sectors due to its lightweight nature, corrosion resistance, aesthetic flexibility, and sustainability. Its proven track record in diverse applications establishes its credibility, making it a trusted solution among professionals who demand both performance and durability. As industries advance, aluminum grating remains at the forefront, offering innovative solutions that meet the intricate needs of modern construction and design.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024