- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 09:14

Back to list

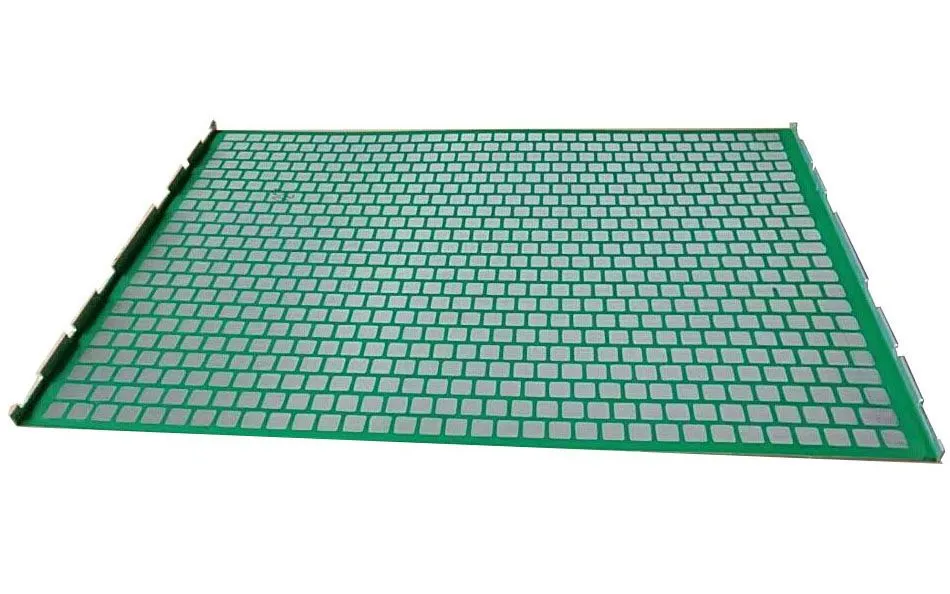

aluminum bar grating weight

Understanding the weight considerations of aluminum bar grating is essential for industries ranging from construction to manufacturing. Known for its remarkable strength-to-weight ratio, aluminum bar grating serves a vital role in various applications, from walkways and platforms to safety barriers. Its lightweight nature does not burden structures while ensuring safety and functionality, making it an ideal material choice for projects where weight is a significant factor.

Incorporating aluminum grating into a project requires a comprehensive understanding of both its mechanical properties and environmental benefits. Unlike heavier metals, aluminum resists corrosion, eliminating the need for complex protective coatings and maintenance. This makes it an economically sensible and environmentally friendly option for many applications. It can be recycled indefinitely without loss of quality, further reducing its carbon footprint and reinforcing its appeal in sustainable building practices. The authority in aluminum grating comes from seasoned manufacturers who provide detailed guides and custom solutions, balancing weight, durability, and price. They are invaluable resources, offering expert advice grounded in real-world testing and industry-specific certifications. Relying on experienced suppliers ensures not only the optimal selection of grating based on weight and span requirements but also adherence to safety standards dictated by governing bodies such as the American National Standards Institute (ANSI). Trust in the chosen material can be bolstered by seeking third-party verification or references from past projects. Gratings that meet independent testing criteria for quality assurance denote a higher level of trustworthiness, providing contractors and engineers with the confidence that the grating will perform as expected under specified conditions. For any project involving aluminum bar grating, balancing the attributes of weight, load capacity, and environmental impact is crucial. By considering the professional insights and industry standards, stakeholders can make informed decisions that ensure the safety, efficiency, and sustainability of their projects. Whether new construction or retrofitting existing structures, the strategic selection of aluminum bar grating based on meticulous weight analysis supports the successful realization of robust, long-lasting installations.

Incorporating aluminum grating into a project requires a comprehensive understanding of both its mechanical properties and environmental benefits. Unlike heavier metals, aluminum resists corrosion, eliminating the need for complex protective coatings and maintenance. This makes it an economically sensible and environmentally friendly option for many applications. It can be recycled indefinitely without loss of quality, further reducing its carbon footprint and reinforcing its appeal in sustainable building practices. The authority in aluminum grating comes from seasoned manufacturers who provide detailed guides and custom solutions, balancing weight, durability, and price. They are invaluable resources, offering expert advice grounded in real-world testing and industry-specific certifications. Relying on experienced suppliers ensures not only the optimal selection of grating based on weight and span requirements but also adherence to safety standards dictated by governing bodies such as the American National Standards Institute (ANSI). Trust in the chosen material can be bolstered by seeking third-party verification or references from past projects. Gratings that meet independent testing criteria for quality assurance denote a higher level of trustworthiness, providing contractors and engineers with the confidence that the grating will perform as expected under specified conditions. For any project involving aluminum bar grating, balancing the attributes of weight, load capacity, and environmental impact is crucial. By considering the professional insights and industry standards, stakeholders can make informed decisions that ensure the safety, efficiency, and sustainability of their projects. Whether new construction or retrofitting existing structures, the strategic selection of aluminum bar grating based on meticulous weight analysis supports the successful realization of robust, long-lasting installations.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024