- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

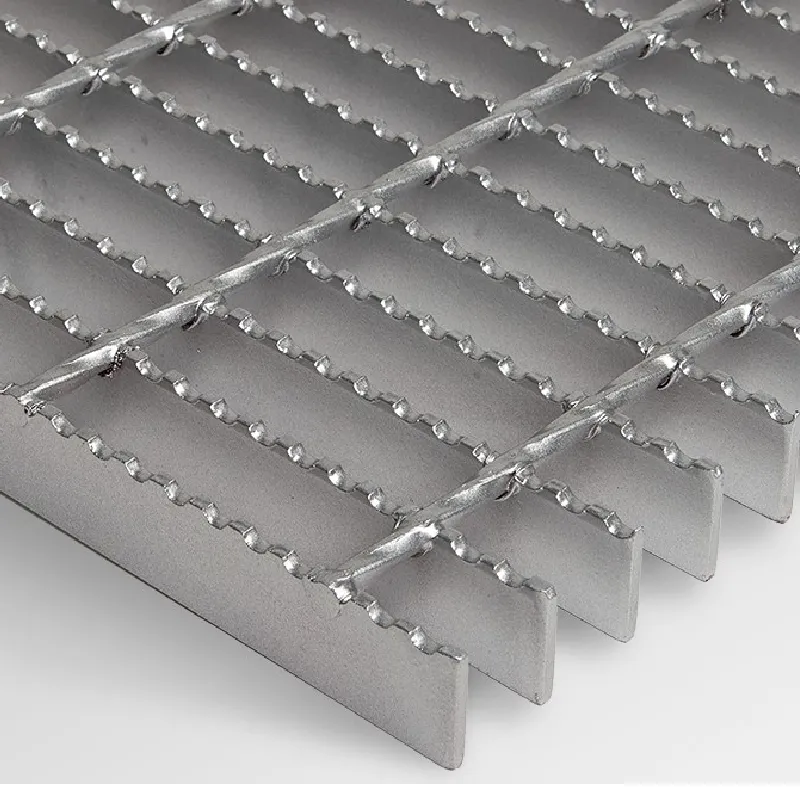

aluminum bar grating

The Versatility and Benefits of Aluminum Bar Grating

Aluminum bar grating is a versatile and practical solution used in various applications, ranging from industrial settings to architectural designs. Known for its durability, lightweight nature, and resistance to corrosion, aluminum bar grating has become a popular choice in the construction and manufacturing industries.

Composition and Design

Aluminum bar grating is made from aluminum alloy, which provides strength without the excessive weight associated with steel. This advantage allows for easier installation and handling, making it ideal for projects where mobility and flexibility are essential. The grating is usually manufactured through a welding process that bonds the bars together, forming a sturdy and reliable structure. The spacing between the bars can be customized according to specific load requirements or environmental conditions, enhancing both functionality and safety.

Key Benefits

One of the primary benefits of aluminum bar grating is its excellent resistance to corrosion. Unlike steel, which can rust and deteriorate over time when exposed to moisture, aluminum naturally forms a protective oxide layer, preventing further oxidation. This feature makes aluminum bar grating particularly suitable for outdoor use, coastal areas, and environments subjected to chemical exposure, such as wastewater treatment plants or food processing facilities.

Additionally, the lightweight nature of aluminum bar grating reduces transportation costs and simplifies the installation process. Workers can easily manage and maneuver large sections of grating without the need for heavy equipment, making it a cost-effective choice for various applications. Moreover, the ease of installation often translates into reduced labor costs, as less time is required for setup.

Aluminum bar grating is also highly customizable. It can be produced in numerous sizes, shapes, and configurations to meet the specific needs of any project. Whether it’s for flooring, walkways, drainage covers, or platforms, aluminum bar grating can be tailored to fit perfectly within the desired space. This flexibility allows architects and engineers to incorporate it into a variety of designs, enhancing both functionality and aesthetics.

aluminum bar grating

Applications

The applications for aluminum bar grating are wide-ranging. In industrial settings, it is commonly utilized for making walkways, stairs, and platforms, providing secure footing while allowing for the easy passage of light and air. Its open design helps prevent water accumulation, reducing slip hazards in environments where liquids may be present.

In commercial buildings, architects often use aluminum bar grating for decorative features, such as screens or facades. Its modern appearance, combined with light filtration properties, can create visually appealing structures that also serve practical purposes. Additionally, aluminum grating can serve in landscaping applications, providing aesthetically pleasing elements while maintaining strength and durability.

Environmental Considerations

Using aluminum bar grating can also contribute to sustainability efforts. Aluminum is a highly recyclable material, and utilizing bar grating made from recycled aluminum can significantly reduce the carbon footprint of a construction project. Additionally, its longevity and minimal maintenance requirements contribute to reducing resource consumption over time.

Conclusion

In summary, aluminum bar grating is a smart choice for a wide range of applications due to its durability, lightweight characteristics, and resistance to corrosion. Its versatility allows it to be customized for specific uses, while its aesthetic appeal makes it suitable for both industrial and architectural purposes. As industries continue to prioritize sustainability and efficiency, the aluminum bar grating presents a compelling option that meets these needs while providing long-lasting performance. Whether in a factory, a commercial building, or a public space, aluminum bar grating stands out as a reliable, effective solution.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024