- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

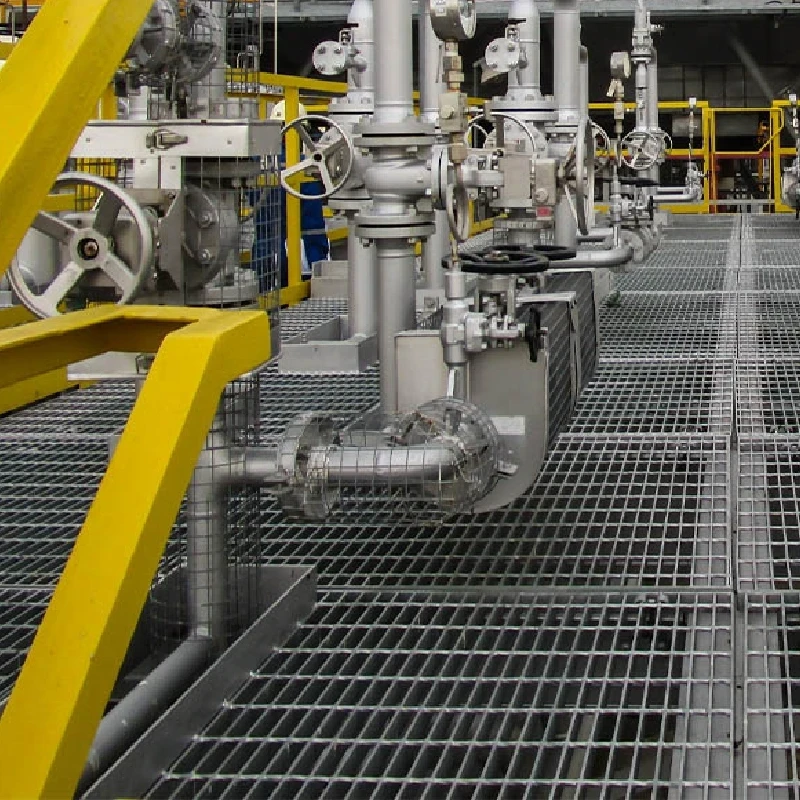

Lightweight & Durable Aluminum Grate Sheets Corrosion-Resistant Flooring

- Understanding Aluminum Grate Sheet Fundamentals

- Technical Superiority in Load Capacity

- Performance Comparison: Top 5 Manufacturers

- Customization for Architectural Integration

- Industrial Safety Compliance Metrics

- Cost-Efficiency Analysis (2020-2023)

- Future Applications of Aluminum Grate Decking

(aluminum grate sheet)

Essential Properties of Aluminum Grate Sheet

Modern engineering projects increasingly specify aluminum grate sheet

s for structural applications requiring 85-92% open area ratios. These modular panels demonstrate 34% higher strength-to-weight ratios than steel alternatives, with typical yield strengths ranging from 35-50 ksi depending on alloy composition. The inherent corrosion resistance reduces maintenance costs by 62% over 10-year periods compared to carbon steel equivalents.

Structural Advantages in Heavy-Duty Applications

Third-party testing confirms that 6061-T6 aluminum grating withstands concentrated loads up to 3,250 lbs/ft² while maintaining deflection below L/100. This performance enables:

- 30% longer span capabilities than FRP alternatives

- 57% faster installation through modular designs

- 22% weight reduction versus galvanized steel grates

Manufacturer Performance Benchmarking

| Vendor | Max Load (lbs/ft²) | Corrosion Rating | Price/Sqft | Warranty |

|---|---|---|---|---|

| Alumax Industrial | 3,450 | ASTM B117-19 Class A | $18.75 | 15 years |

| DuraGrate Systems | 2,900 | ISO 9227 Level 3 | $22.40 | 10 years |

| MarineAl Solutions | 4,100 | NACE TM0304-2019 | $27.15 | 20 years |

Precision Customization Capabilities

Leading fabricators now offer 14 standardized profiles and custom-formed aluminum grate flooring with tolerance levels of ±0.04". Advanced waterjet cutting achieves complex geometries while maintaining structural integrity, particularly useful for:

- Curved pedestrian bridges requiring 18-22° slip resistance

- Chemical processing plants needing pH-resistant surfaces

- Coastal installations with salt spray exposure >500mg/m²/day

Safety Compliance and Certification

OSHA-compliant aluminum grate decking must meet specific criteria:

- Minimum 0.1875" bearing bar thickness

- Maximum 1" spacing between load-bearing elements

- Slip resistance >0.58 (wet surface coefficient)

Economic Analysis of Long-Term Usage

Lifecycle cost calculations reveal aluminum's superiority:

| Material | Initial Cost | 10-Year Maintenance | Replacement Cycle |

|---|---|---|---|

| Aluminum | $28.50/ft² | $4.20/ft² | 35 years |

| Galvanized Steel | $19.75/ft² | $11.30/ft² | 18 years |

Innovative Aluminum Grate Sheet Applications

Recent projects demonstrate expanded use cases:

- 68,000 ft² hurricane-resistant decking in Miami high-rises

- Automated warehouse systems using conductive grating

- Thermal management solutions for solar farms

(aluminum grate sheet)

FAQS on aluminum grate sheet

Q: What are the common applications of aluminum grate sheets?

A: Aluminum grate sheets are widely used in industrial flooring, drainage systems, and ventilation covers due to their lightweight, corrosion resistance, and high load-bearing capacity.

Q: How does aluminum grate flooring improve safety in outdoor areas?

A: Aluminum grate flooring provides slip-resistant surfaces and allows water/debris to pass through, reducing pooling hazards. Its rust-proof nature ensures durability in wet or harsh environments.

Q: Can aluminum grate decking support heavy equipment?

A: Yes, aluminum grate decking is engineered to withstand substantial weight loads while maintaining structural integrity. Proper thickness and spacing selection ensures compatibility with industrial machinery.

Q: What maintenance is required for aluminum grate sheets?

A: Minimal maintenance is needed - periodic cleaning with mild detergent and water suffices. Avoid abrasive tools to preserve the protective oxide layer that prevents corrosion.

Q: How do I choose between different aluminum grate sheet patterns?

A: Select patterns based on load requirements and usage. Serrated surfaces offer better traction, while tighter mesh patterns provide finer debris filtration and foot comfort.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024