- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Cost of Aluminum Grating and Factors Influencing Price Variations in the Market

Understanding the Pricing of Aluminium Grating

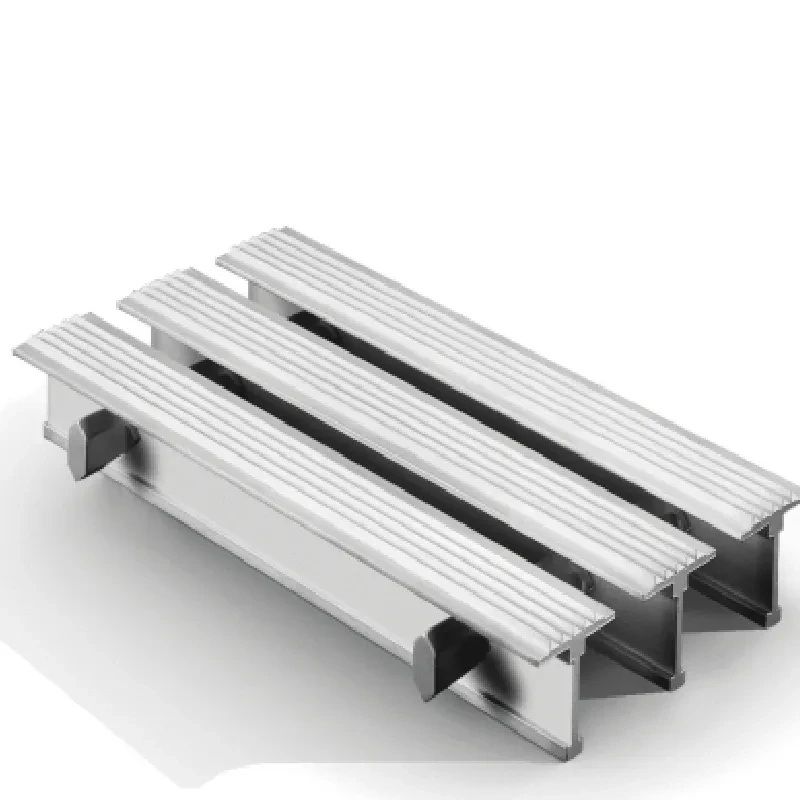

Aluminium grating is a popular choice for various industrial and commercial applications due to its lightweight, corrosion resistance, and durability. As demand for eco-friendly and sustainable materials grows, many industries are turning to aluminium grating for flooring, walkways, and drainage solutions. However, the price of aluminium grating can vary widely based on several factors, which we will explore in this article.

Factors Influencing Aluminium Grating Prices

1. Material Quality The type and quality of aluminium used in the grating significantly affect the price. Higher grades of aluminium, which offer better strength and resistance to corrosion, generally cost more. Additionally, the presence of additives or coatings for increased durability can also impact pricing.

2. Manufacturing Process The method used to fabricate the grating — whether it is welded, forged, or extruded — can influence costs. Advanced manufacturing techniques that enhance the performance and longevity of the grating may lead to higher prices.

3. Size and Design Aluminium grating comes in various sizes and designs, including different thicknesses and shapes. Custom sizes and intricate designs require additional engineering and manufacturing, which can raise the price significantly compared to standard options.

4. Quantity Ordered Bulk purchasing often results in discounts. Larger orders can significantly reduce the per-unit cost, making it more economical for large projects or repeated use.

aluminium grating price

5. Market Demand As with any commodity, the cost of aluminium grating can fluctuate based on supply and demand dynamics. For instance, during a construction boom, the increased demand for raw materials, including aluminium, can drive prices up.

6. Geographical Location The prices can vary based on location due to shipping costs and local market conditions. In some regions, the availability of aluminium may be restricted, leading to higher prices.

Trends in Aluminium Grating Pricing

In recent years, there has been a notable shift toward the use of recycled aluminium, which has implications for both cost and sustainability. Recycled materials can lower overall costs and lessen the environmental impact of production. As technology advances, the efficiency of manufacturing processes is improving, which may contribute to stabilizing or reducing prices over time.

Conclusion

When considering aluminium grating for a project, it is essential to take into account the various factors affecting pricing. Understanding the specifics related to material quality, manufacturing processes, and market conditions can help stakeholders make informed decisions. Whether for industrial use or architectural applications, investing in aluminium grating can offer long-lasting benefits, making it a worthwhile consideration despite the variations in cost. Always compare prices from different suppliers and consider long-term value over initial expenditure to ensure a successful investment.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024