- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Affordable Pricing Options for Galvanized Grating in Various Sizes and Specifications

Understanding the Pricing of Galvanized Grating

Galvanized grating has become an essential component in various industrial and commercial applications due to its durability, corrosion resistance, and versatility. The prices of galvanized grating can vary significantly based on multiple factors, and understanding these can assist both consumers and businesses in making informed purchasing decisions.

What is Galvanized Grating?

Galvanized grating refers to steel grating that has undergone a hot-dip galvanization process to protect it from corrosion and rust. This method involves dipping steel grates into molten zinc, creating a protective layer that enhances their longevity, especially in harsh environmental conditions. Galvanized grating is widely used in pedestrian walkways, platforms, drainage covers, and in various industrial facilities.

Factors Influencing the Price of Galvanized Grating

1. Material Quality The type of steel used in the production of galvanized grating significantly impacts its price. High-quality steel, while more expensive, provides better structural integrity and a longer lifespan.

2. Grating Type There are different types of galvanized grating, such as welded, riveted, and swage-locked. Each type has unique manufacturing processes and material usage, affecting the cost. For instance, welded grating, known for its strength and stability, tends to be more expensive than other types due to the complexity of its production.

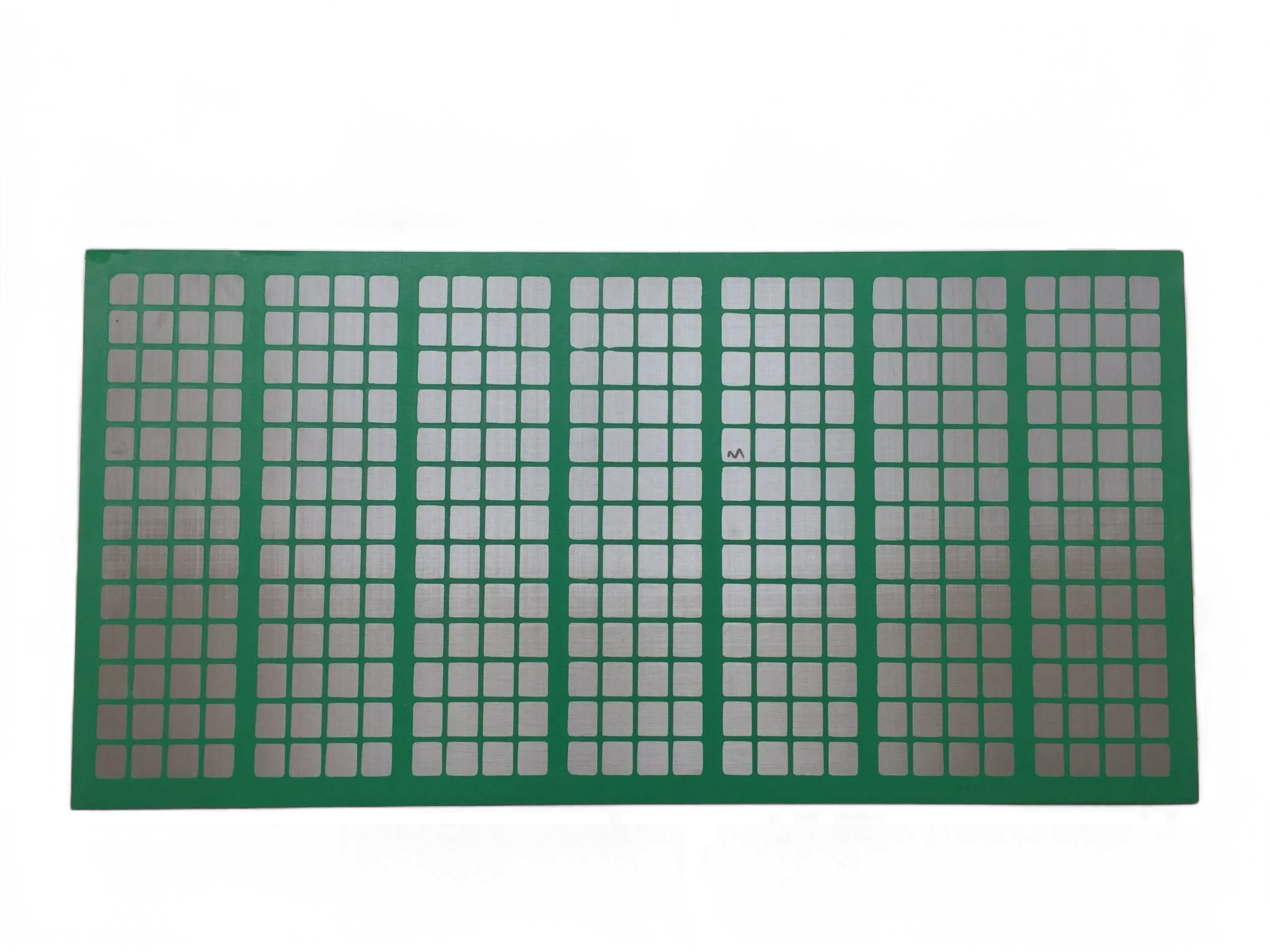

galvanized grating price

3. Thickness and Load Capacity The thickness of the grating and the load it is designed to support are crucial in determining price. Thicker and heavier duty grating can withstand more weight and is often more costly than lighter alternatives. Buyers must assess their specific needs to select the appropriate type without overspending on unnecessary features.

4. Surface Finish Beyond hot-dip galvanization, additional surface treatments, such as powder coating, can enhance aesthetics and grip but will also contribute to the overall cost. The choice of finish should align with the intended use of the grating.

5. Size and Customization Standard sizes of galvanized grating are generally cheaper than custom-made options. When businesses or contractors require specific dimensions for a project, the price can increase due to the additional materials and labor involved.

6. Supplier and Location Prices can vary considerably based on the supplier's location and pricing strategy. Local suppliers may offer better shipping rates, while others may charge premium prices based on demand or geographical factors. It’s often beneficial to obtain quotes from multiple suppliers to find the best deal.

7. Market Trends Like any commodity, the price of galvanized grating can be influenced by market trends, including fluctuations in steel prices, changes in demand, and broader economic conditions. Awareness of these trends can help buyers anticipate price changes and time their purchases accordingly.

Conclusion

The price of galvanized grating is influenced by a multitude of factors, ranging from the type and quality of materials used to market conditions. For consumers and businesses considering the purchase of galvanized grating, understanding these dynamics is vital. By evaluating specific needs, obtaining multiple quotes, and staying informed about market trends, buyers can make more informed decisions, ensuring they invest in the right product at a fair price. With its robust qualities and versatility, galvanized grating remains a smart choice for those seeking reliable solutions for industrial and commercial applications.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024