- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 17:15

Back to list

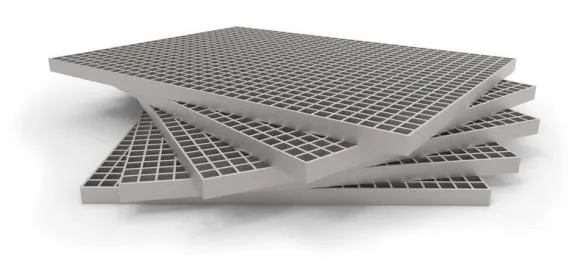

Steel Grating

Navigating the intricate world of industrial products often presents challenges, particularly when it comes to choosing the right materials for specific applications. Within this landscape, a325 grating emerges not merely as a product reference but as a pivotal component in numerous industrial settings, renowned for its strength and versatility.

From a professional perspective, the installation of a325 grating benefits from straightforward assembly and minimal maintenance requirements. The precision engineering of its components ensures that fittings are secure and stable, ensuring a long service life with low upkeep costs. This aspect is particularly appreciated by project managers and engineers who prioritize cost-effectiveness without compromising on quality. Trust plays a crucial role in the adoption of any industrial product, and a325 grating commands it through consistent performance and compliance with international standards. Manufacturers of this grating type are committed to rigorous quality assurance processes, delivering products that meet or exceed industry expectations. In looking to the future, advancements in materials technology continue to enhance the capabilities of a325 grating, promising even greater performance metrics and suitability for a wider array of applications. As industries evolve, the development of lighter yet stronger grating options that retain the a325 designation may serve as a testament to the ongoing innovation in the field. Conclusively, a325 grating represents more than a mere component; it embodies the intersection of engineering excellence, reliability, and safety. For decision-makers in industrial sectors, understanding its attributes and potential applications can lead to more informed choices, securing operational efficiency and advancing structural integrity across various projects.

From a professional perspective, the installation of a325 grating benefits from straightforward assembly and minimal maintenance requirements. The precision engineering of its components ensures that fittings are secure and stable, ensuring a long service life with low upkeep costs. This aspect is particularly appreciated by project managers and engineers who prioritize cost-effectiveness without compromising on quality. Trust plays a crucial role in the adoption of any industrial product, and a325 grating commands it through consistent performance and compliance with international standards. Manufacturers of this grating type are committed to rigorous quality assurance processes, delivering products that meet or exceed industry expectations. In looking to the future, advancements in materials technology continue to enhance the capabilities of a325 grating, promising even greater performance metrics and suitability for a wider array of applications. As industries evolve, the development of lighter yet stronger grating options that retain the a325 designation may serve as a testament to the ongoing innovation in the field. Conclusively, a325 grating represents more than a mere component; it embodies the intersection of engineering excellence, reliability, and safety. For decision-makers in industrial sectors, understanding its attributes and potential applications can lead to more informed choices, securing operational efficiency and advancing structural integrity across various projects.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024