- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 05, 2025 02:56

Back to list

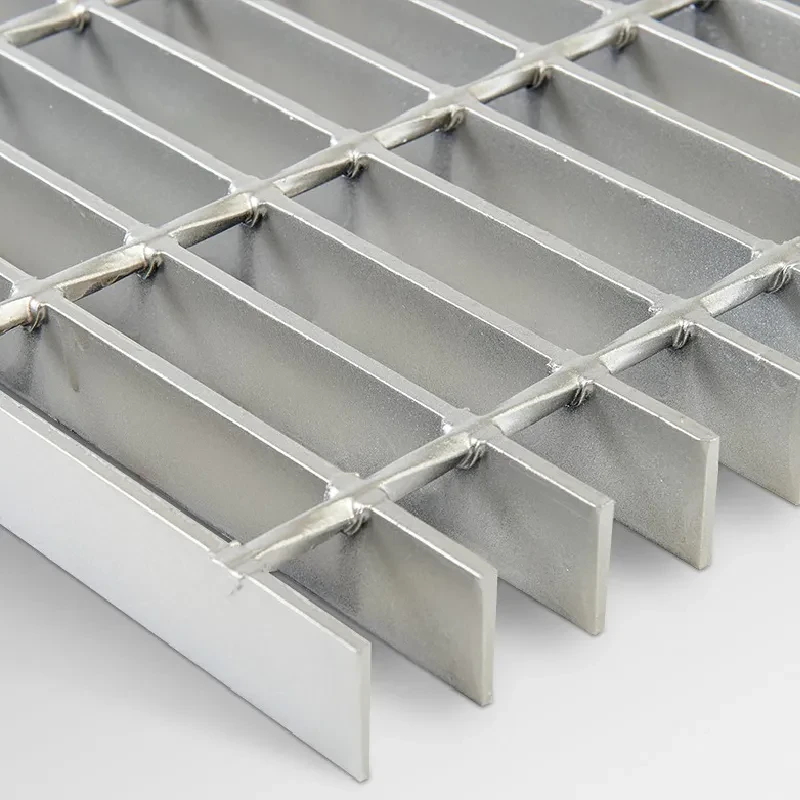

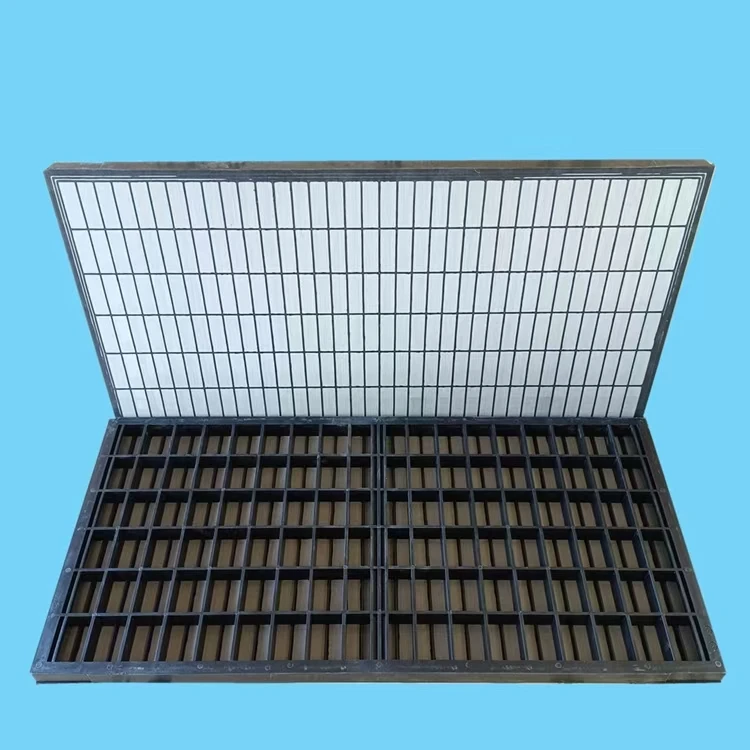

walkway grates

Trench drain systems are essential components of modern infrastructure, providing efficient solutions to water drainage problems in a variety of settings. Among the crucial elements of a successful trench drain system are the grates that cover them. For those who seek quality, functionality, and innovation, 8 trench drain grates offer compelling options worthy of consideration.

For professionals and procurement specialists, the authoritativeness of these trench drain grates is backed by compliance with industry standards and certifications. Many manufacturers of the 8 trench drain grates adhere to rigorous testing procedures which align with ISO or ASTM standards, providing peace of mind that these products meet or exceed safety and performance benchmarks. Trust in these grates is fostered through a track record of reliability and endorsements by industry experts. On the ground level, user experience with these grates underscores the product’s trustworthiness and efficiency. Installation processes are streamlined with intuitive designs and clear instructions—often requiring minimal tools, thereby reducing labor time and costs. Property managers and civil engineers frequently report positive outcomes post-installation, noting a significant decrease in maintenance issues and satisfactory aesthetic integration into their projects. Sustainability is also a growing concern, and the 8 trench drain grates are keeping pace with eco-friendly trends. Many models are composed of recyclable materials, and certain manufacturers have even introduced environmentally benign production processes, thus appealing to environmentally conscious customers and projects aiming for LEED certifications. Ultimately, selecting the right trench drain grate is an investment in infrastructure integrity. The 8 trench drain grates are designed with a deep understanding of user needs, industry requirements, and environmental sustainability, showcasing a careful balance between form and function. For anyone involved in building or renovating spaces where water management is crucial, exploring these grates could offer significant benefits both in the short-term efficacy and long-term resilience of their drainage systems.

For professionals and procurement specialists, the authoritativeness of these trench drain grates is backed by compliance with industry standards and certifications. Many manufacturers of the 8 trench drain grates adhere to rigorous testing procedures which align with ISO or ASTM standards, providing peace of mind that these products meet or exceed safety and performance benchmarks. Trust in these grates is fostered through a track record of reliability and endorsements by industry experts. On the ground level, user experience with these grates underscores the product’s trustworthiness and efficiency. Installation processes are streamlined with intuitive designs and clear instructions—often requiring minimal tools, thereby reducing labor time and costs. Property managers and civil engineers frequently report positive outcomes post-installation, noting a significant decrease in maintenance issues and satisfactory aesthetic integration into their projects. Sustainability is also a growing concern, and the 8 trench drain grates are keeping pace with eco-friendly trends. Many models are composed of recyclable materials, and certain manufacturers have even introduced environmentally benign production processes, thus appealing to environmentally conscious customers and projects aiming for LEED certifications. Ultimately, selecting the right trench drain grate is an investment in infrastructure integrity. The 8 trench drain grates are designed with a deep understanding of user needs, industry requirements, and environmental sustainability, showcasing a careful balance between form and function. For anyone involved in building or renovating spaces where water management is crucial, exploring these grates could offer significant benefits both in the short-term efficacy and long-term resilience of their drainage systems.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024