- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

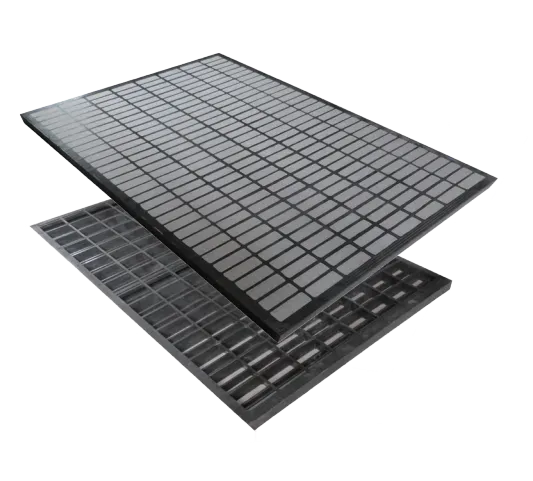

Durable 316 Stainless Steel Grating for Enhanced Structural Support and Versatility

Understanding 316 Stainless Steel Grating A Versatile Solution for Various Applications

316 stainless steel grating has emerged as a popular choice in industries where durability, corrosion resistance, and structural integrity are paramount. Its unique properties make it an ideal material for numerous applications across various environments, from marine settings to chemical processing plants.

One of the most significant advantages of 316 stainless steel grating is its remarkable resistance to corrosion. This type of stainless steel contains molybdenum, which enhances its ability to withstand harsh environments, particularly those exposed to saltwater and acidic conditions. As a result, 316 stainless steel grating is widely used in marine applications, such as docks, piers, and walkways, where exposure to seawater can quickly deteriorate lesser materials. This corrosion resistance ensures a longer lifespan for the grating, reducing the need for frequent replacements and maintenance.

In addition to its corrosion resistance, 316 stainless steel grating is known for its strength and durability. The structural integrity of this material makes it suitable for heavy-duty applications, where it can support substantial loads without compromising safety. This feature is particularly valuable in industrial settings, such as manufacturing plants, where equipment and personnel rely on sturdy flooring systems. The slip-resistant surface of 316 stainless steel grating further enhances safety, making it an excellent choice for environments that require careful footing.

316 stainless steel grating

Another important aspect of 316 stainless steel grating is its versatility. It can be fabricated into various styles and sizes, including welded, swage-locked, and riveted configurations. This adaptability allows for customization to meet specific project requirements, whether it's for a catwalk, platform, or drainage cover. The grating can also be easily integrated with other materials, such as concrete or timber, expanding its potential use in diverse design frameworks.

Maintenance of 316 stainless steel grating is relatively straightforward, as regular cleaning can help maintain its aesthetic appeal and functionality. Unlike other materials that may require specialized coatings or treatments, 316 stainless steel is resistant to staining and rusting, making it easy to upkeep over time. This ease of maintenance translates to cost savings for businesses and facilities, further enhancing the material's attractiveness.

In conclusion, 316 stainless steel grating is a superior choice for applications requiring resilience against harsh conditions, structural strength, and low maintenance. Its unique properties make it indispensable in various industries, providing long-lasting solutions that ensure safety and efficiency. Whether used in commercial, industrial, or marine environments, 316 stainless steel grating proves to be a reliable and versatile material that meets the demands of modern applications. As industries continue to prioritize durability and safety, the popularity of 316 stainless steel grating is set to grow, reinforcing its status as a trusted choice in construction and engineering.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024