- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 21:58

Back to list

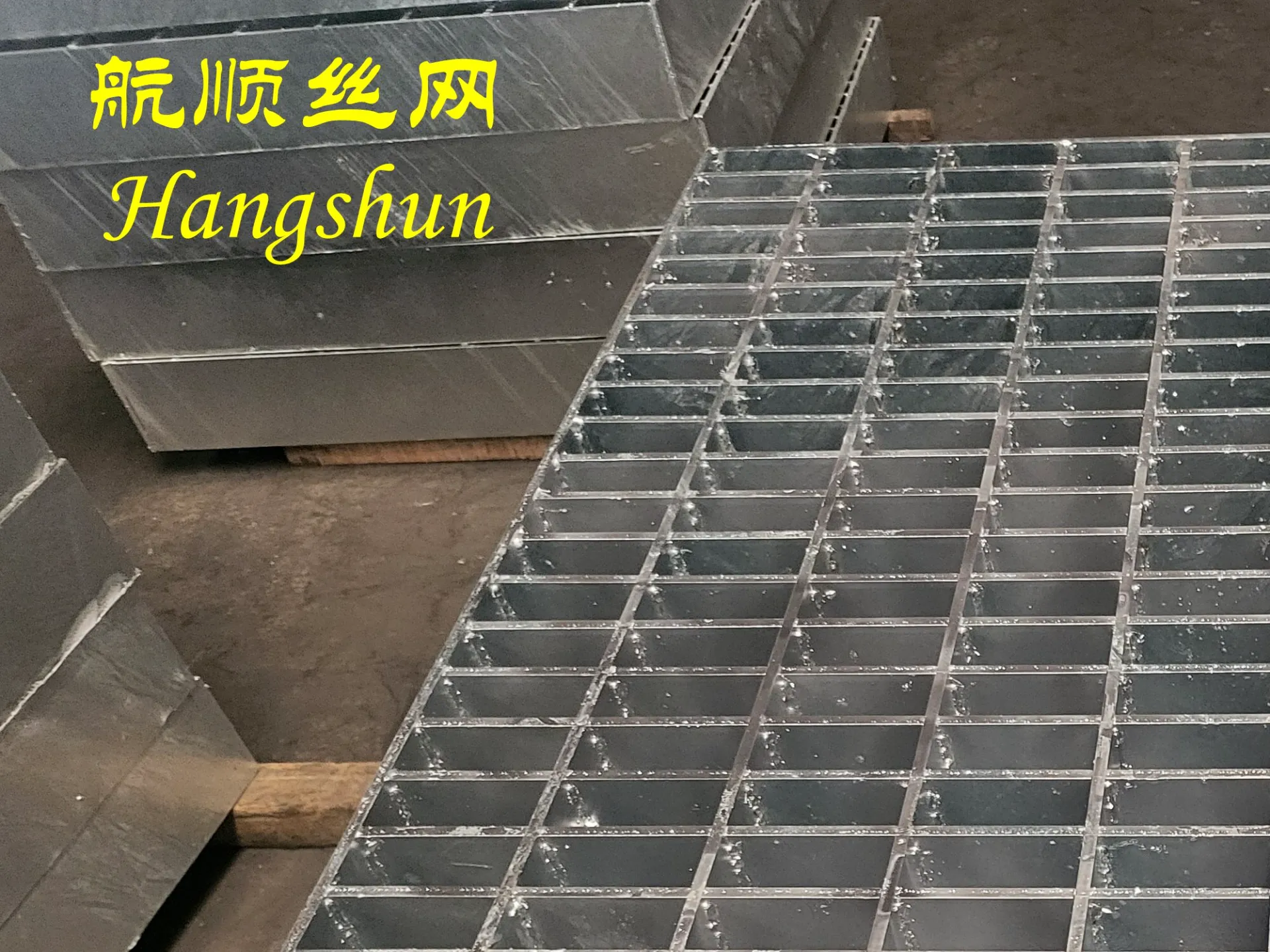

steel walkway grating

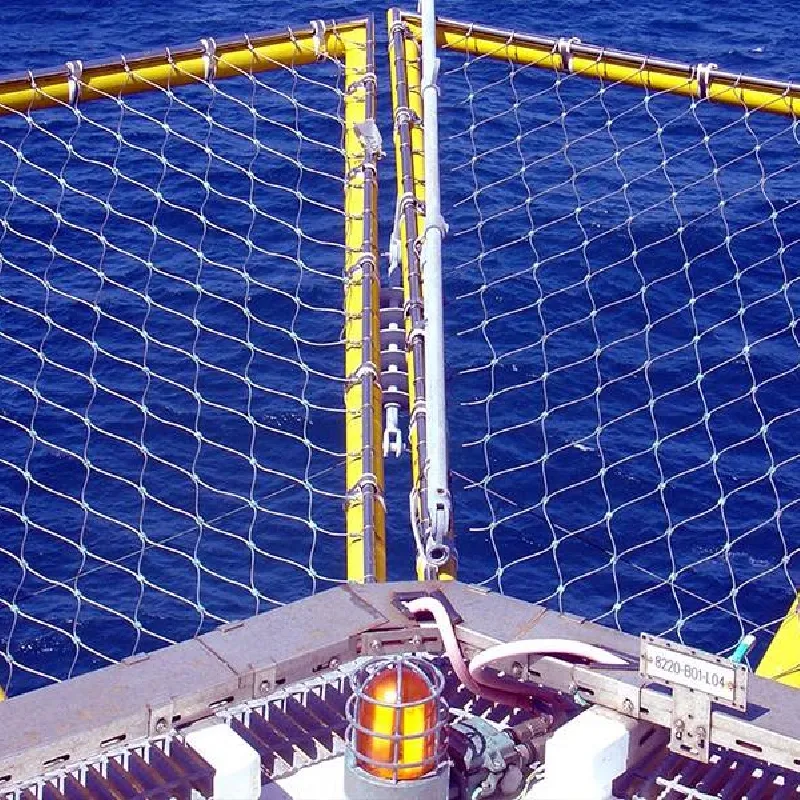

Steel grating, an essential material in various industrial and architectural sectors, offers myriad advantages that make it a preferred choice for flooring, walkways, platforms, and more. Understanding its intricacies not only helps in selecting the right product but also enhances the overall safety and efficiency of its application. This article delves into the practical experiences, professional insights, authoritative references, and the trustworthiness that defines steel grating's usage across industries.

Authoritative sources recommend regular maintenance and inspection of steel grating to ensure its longevity and effectiveness. These practices include checking for signs of wear and tear, rust, and any structural weaknesses that could compromise safety. Industry standards, such as those established by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI), provide guidelines that ensure steel grating is used safely and effectively. Compliance with these standards not only enhances operational safety but also extends the lifespan of the grating itself. The trustworthiness of steel grating as a reliable material is reinforced by its consistent performance record in critical applications. Case studies often cite its usage in high-traffic areas, where it has successfully supported operations without significant maintenance or safety issues. Feedback from industry experts also underscores its cost-effectiveness in the long term; while the initial investment might be higher compared to alternative materials, the durability and low upkeep costs make steel grating a financially prudent choice. In conclusion, steel grating emerges as a critical component across various sectors, driven by its strength, versatility, and safety features. It stands as a testament to what carefully selected materials can achieve in enhancing operational efficiency and maintaining safety standards. A deeper understanding of its properties, backed by professional insights and authoritative guidelines, ensures that businesses can make informed decisions, fostering trust and reliability in their infrastructure.

Authoritative sources recommend regular maintenance and inspection of steel grating to ensure its longevity and effectiveness. These practices include checking for signs of wear and tear, rust, and any structural weaknesses that could compromise safety. Industry standards, such as those established by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI), provide guidelines that ensure steel grating is used safely and effectively. Compliance with these standards not only enhances operational safety but also extends the lifespan of the grating itself. The trustworthiness of steel grating as a reliable material is reinforced by its consistent performance record in critical applications. Case studies often cite its usage in high-traffic areas, where it has successfully supported operations without significant maintenance or safety issues. Feedback from industry experts also underscores its cost-effectiveness in the long term; while the initial investment might be higher compared to alternative materials, the durability and low upkeep costs make steel grating a financially prudent choice. In conclusion, steel grating emerges as a critical component across various sectors, driven by its strength, versatility, and safety features. It stands as a testament to what carefully selected materials can achieve in enhancing operational efficiency and maintaining safety standards. A deeper understanding of its properties, backed by professional insights and authoritative guidelines, ensures that businesses can make informed decisions, fostering trust and reliability in their infrastructure.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024