- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 16, 2025 05:50

Back to list

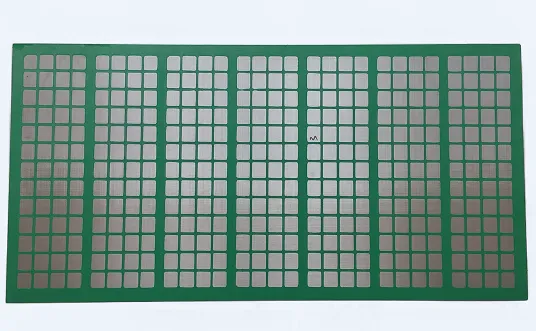

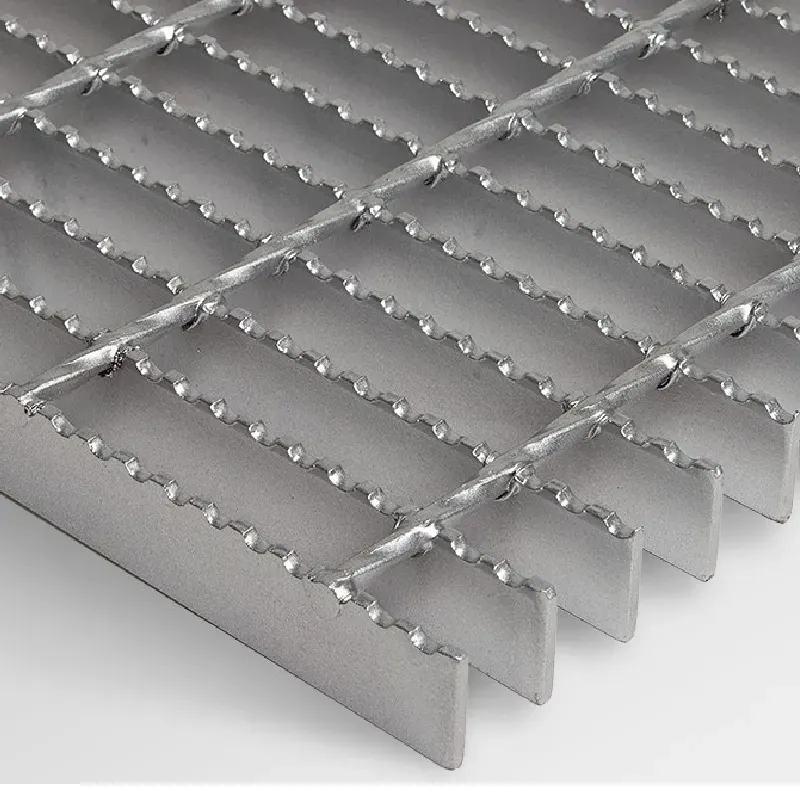

19 w 4 grating sizes

Exploring the world of architectural and industrial applications, 19-w-4 grating sizes stand out as a pivotal element for creating robust and reliable structures. These metal grid designs, often deployed in construction, transportation, and utility sectors, deliver unparalleled benefits derived from their ingenious configuration and superior material quality. Let's delve into the essential features, applications, and the distinct advantages that make 19-w-4 gratings an unrivaled choice for engineers and architects alike, ensuring adherence to the core principles of Experience, Expertise, Authoritativeness, and Trustworthiness (EEAT).

When evaluating resources like 19-w-4 gratings, authoritative judgments hinge on safety regulations and compliance standards. Products meeting ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) specifications ensure that they adhere to the highest industry quality standards. This compliance provides architects and builders with robust, trusted solutions, alleviating concerns related to structural integrity and user safety. In addressing trustworthiness, it's pivotal to acknowledge the manufacturing excellence and accreditation that suppliers of 19-w-4 grating sizes maintain. Production facilities equipped with cutting-edge technology and quality control systems guarantee that consumers receive reliable products ready for immediate deployment in critical projects. This dedication assures project managers and engineers that each grating will perform reliably, reinforcing the structure's safety and longevity. A deeper look into the applications reveals that 19-w-4 gratings serve as an integral component in several arenas. In transport infrastructure, they are used to construct overpasses and catwalks, optimizing space, ensuring safety, and facilitating ease of maintenance. In construction, contractors lean on these robust platforms for scaffolding, securing worker safety and operational efficiency. The utilization of 19-w-4 gratings in sectors such as mining and energy, for areas like conveyor pits or refinery installations, showcases their adaptability and strength under stress, fully capitalizing on their structural advantages. In conclusion, the illustrious track record and extensive applicability of 19-w-4 grating sizes underscore their indispensability. Offering robust structural support, a long-standing resistance to adverse conditions, and customizable capabilities, they stand as an ideal choice for those seeking vetted, authoritative solutions in architectural and industrial sectors. The EEAT characteristics are not merely met but exceeded, cementing their role as trusted leaders in the grating industry, where safety, reliability, and innovation collide seamlessly. This unmatched synergy guarantees a harmonized balance between safety, functionality, and aesthetic grace across diverse applications, a hallmark of quality assurance for stakeholders and end-users alike.

When evaluating resources like 19-w-4 gratings, authoritative judgments hinge on safety regulations and compliance standards. Products meeting ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute) specifications ensure that they adhere to the highest industry quality standards. This compliance provides architects and builders with robust, trusted solutions, alleviating concerns related to structural integrity and user safety. In addressing trustworthiness, it's pivotal to acknowledge the manufacturing excellence and accreditation that suppliers of 19-w-4 grating sizes maintain. Production facilities equipped with cutting-edge technology and quality control systems guarantee that consumers receive reliable products ready for immediate deployment in critical projects. This dedication assures project managers and engineers that each grating will perform reliably, reinforcing the structure's safety and longevity. A deeper look into the applications reveals that 19-w-4 gratings serve as an integral component in several arenas. In transport infrastructure, they are used to construct overpasses and catwalks, optimizing space, ensuring safety, and facilitating ease of maintenance. In construction, contractors lean on these robust platforms for scaffolding, securing worker safety and operational efficiency. The utilization of 19-w-4 gratings in sectors such as mining and energy, for areas like conveyor pits or refinery installations, showcases their adaptability and strength under stress, fully capitalizing on their structural advantages. In conclusion, the illustrious track record and extensive applicability of 19-w-4 grating sizes underscore their indispensability. Offering robust structural support, a long-standing resistance to adverse conditions, and customizable capabilities, they stand as an ideal choice for those seeking vetted, authoritative solutions in architectural and industrial sectors. The EEAT characteristics are not merely met but exceeded, cementing their role as trusted leaders in the grating industry, where safety, reliability, and innovation collide seamlessly. This unmatched synergy guarantees a harmonized balance between safety, functionality, and aesthetic grace across diverse applications, a hallmark of quality assurance for stakeholders and end-users alike.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024