- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 31, 2025 03:44

Back to list

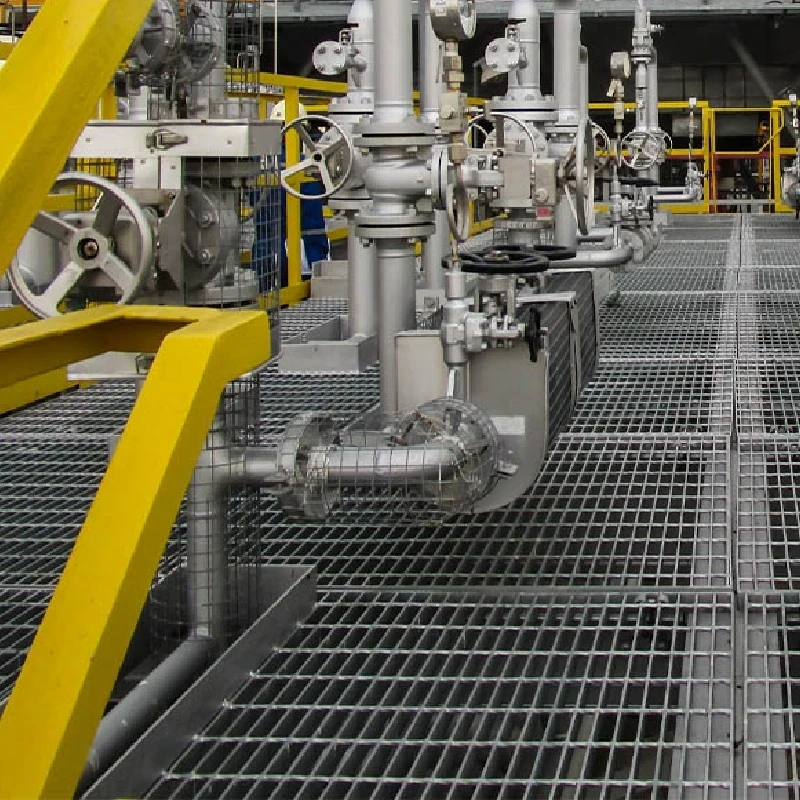

steel walkway grating

Navigating the universe of grating sizes, especially when it comes to 19 w 4 grating sizes, often requires a nuanced understanding to ensure optimal selection for varied applications. Within industrial and architectural domains, gratings play a critical role in both functionality and aesthetic appeal, serving as flooring, drainage covers, stair treads, and walkways. The specificity of 19 w 4 refers to a particular grating style, known for its robustness and adaptability, applicable in myriad settings.

Expanding expertise in grating involves appreciating how installation impacts both functionality and lifespan. Easy to install and maintain, 19 w 4 gratings can be custom-fitted to any space configurations, thus minimizing waste and reducing installation time. In the real world, installation methods may employ welding or bolting, each suited to distinct industrial requirements. Welding can offer a more permanent integration, while bolting provides flexibility in terms of component replacement and maintenance. Finally, the endorsement and trustworthiness of any product type grow exponentially through adherence to standards and specifications. 19 w 4 grating sizes comply with numerous safety standards including those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). Products that meet such certifications instill confidence in patrons, ensuring that investments adhere to the highest levels of safety and quality, reflecting the ultimate in industrial professionalism. In conclusion, selecting the appropriate grating size, particularly 19 w 4, involves considering a mix of safety, functionality, and material effectiveness. Its widespread acceptance is built on a foundation of proven performance and durability in demanding environments. As industries evolve, so too do their needs for reliable infrastructure solutions; here, the time-tested engineering of 19 w 4 grating sizes continues to set a benchmark in strength, reliability, and efficiency. In the world of industrial and structural design, such gratings are not just components, but critical elements shaping modern safety and operational standards.

Expanding expertise in grating involves appreciating how installation impacts both functionality and lifespan. Easy to install and maintain, 19 w 4 gratings can be custom-fitted to any space configurations, thus minimizing waste and reducing installation time. In the real world, installation methods may employ welding or bolting, each suited to distinct industrial requirements. Welding can offer a more permanent integration, while bolting provides flexibility in terms of component replacement and maintenance. Finally, the endorsement and trustworthiness of any product type grow exponentially through adherence to standards and specifications. 19 w 4 grating sizes comply with numerous safety standards including those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). Products that meet such certifications instill confidence in patrons, ensuring that investments adhere to the highest levels of safety and quality, reflecting the ultimate in industrial professionalism. In conclusion, selecting the appropriate grating size, particularly 19 w 4, involves considering a mix of safety, functionality, and material effectiveness. Its widespread acceptance is built on a foundation of proven performance and durability in demanding environments. As industries evolve, so too do their needs for reliable infrastructure solutions; here, the time-tested engineering of 19 w 4 grating sizes continues to set a benchmark in strength, reliability, and efficiency. In the world of industrial and structural design, such gratings are not just components, but critical elements shaping modern safety and operational standards.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024