- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

19w4 bar grating weight

Understanding the Weight of 19W4% Bar Grating

When it comes to industrial applications, bar grating plays a crucial role in various sectors, ranging from construction to automotive and manufacturing. Among the different types of bar grating available in the market, the 19W4% bar grating stands out due to its robust construction and versatility. One notable aspect that engineers and designers often consider when selecting the right grating is its weight. This article explores the significance of understanding the weight of 19W4% bar grating and its implications for project planning and execution.

What is 19W4% Bar Grating?

19W4% bar grating is a type of steel grating characterized by its specific design. The 19 refers to the spacing between the bearing bars, which is 19 mm, while W4 denotes the width of the bars, typically about 4 mm. The % symbol indicates that the openings occupy a certain percentage of the total area of the grating. This design provides excellent strength, durability, and corrosion resistance, making it suitable for heavy-duty applications, including walkways, platforms, and industrial flooring.

The Importance of Knowing the Weight

Understanding the weight of bar grating is critical for several reasons

19w4 bar grating weight

1. Structural Integrity The weight of the grating contributes to the overall load-bearing capacity of the structure in which it is installed. Hence, it needs to be calculated according to the span and load that the grating will support. It is essential to ensure that the supporting structure can handle the combined weight of the grating itself along with any additional loads without compromising stability.

2. Material Handling and Installation Knowledge of the weight helps teams manage logistics effectively. Bar grating can be heavy, depending on its size and material. Understanding the weight allows for better planning regarding transport, lifting equipment, and installation techniques, which can help reduce injury risks and enhance efficiency on-site.

3. Cost Implications The weight of the grating affects shipping costs and overall project expenses. Gratings with higher weights may incur higher transport fees, and this factor should be included in the budgeting phase of a project. Additionally, heavier gratings might require more robust supporting structures, leading to increased material costs.

4. Safety Compliance Different industries are governed by specific safety standards that dictate load capacities. Knowing the weight of a grating like the 19W4% allows project managers to align with these regulations, ensuring that their installations are compliant and safe for users.

Conclusion

In conclusion, understanding the weight of 19W4% bar grating is essential for engineering, construction, and maintenance professionals. Not only does it play a critical role in ensuring structural integrity and safety, but it also impacts material handling and the overall economics of a project. As industries continue to evolve, the demand for reliable and efficient bar grating solutions like the 19W4% will persist, and so will the importance of meticulous planning based on their weight characteristics. Therefore, professionals must always consider this crucial factor when planning an installation to ensure project success and safety.

-

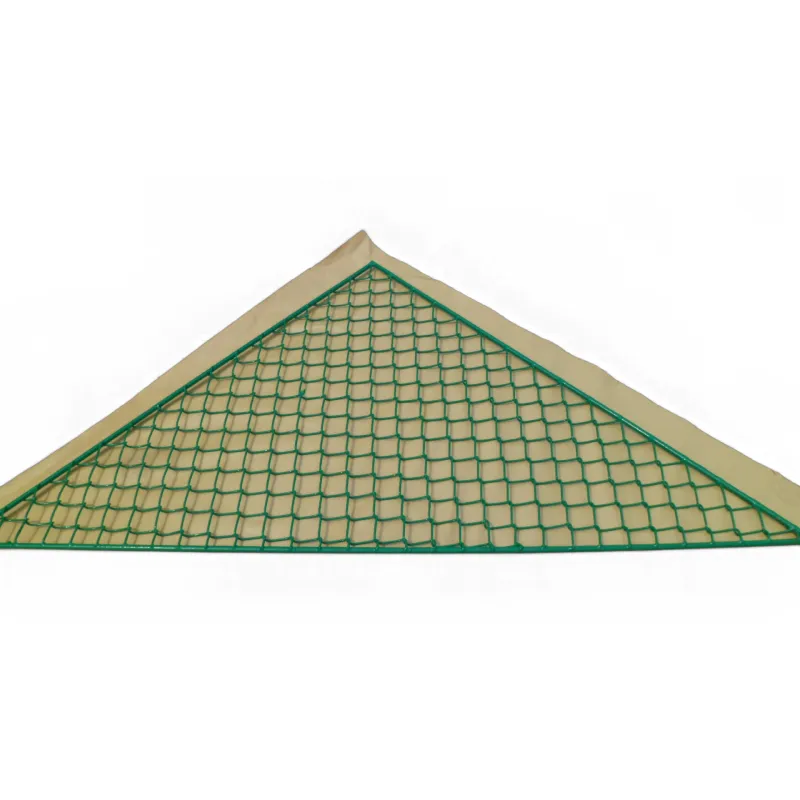

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024